Scientists Develop Eco-Friendly Concrete Alternative From Sugarcane Waste, Called Sugarcrete

In a world where climate change, housing shortages, and construction waste are colliding like never before, a new material is rising quietly—but powerfully—out of the sugarcane fields. It’s called Sugarcrete, and despite sounding like something you’d sprinkle on top of a cupcake, it may very well be the future of green architecture.

Developed by researchers who saw more than just waste in sugarcane’s byproducts, Sugarcrete is a lightweight, eco-friendly building material made from bagasse—the fibrous remains of sugarcane after juice extraction. It promises to revolutionize construction by offering a cleaner, cheaper, and surprisingly stronger alternative to concrete and clay bricks.

But to really understand why this matters, we need to look at the bigger picture.

🌍 Why We Need to Rethink What We Build With

Traditional construction has long relied on concrete, a blend of cement, sand, gravel, and water that hardens into the grey slabs we see everywhere—from skyscrapers to sidewalks. It’s strong, dependable, and widely used.

However, there’s a hidden cost.

- Cement production alone contributes to around 8% of global CO₂ emissions, more than the aviation industry.

- It’s also energy-intensive, requiring extremely high temperatures—often generated by burning fossil fuels.

- The extraction of raw materials like limestone and sand leads to environmental damage, habitat loss, and soil erosion.

Meanwhile, the world’s need for housing is only growing. According to the United Nations, nearly 3 billion people will need access to affordable housing by 2030. That means more buildings, more materials, and—unless something changes—a whole lot more pollution.

That’s where Sugarcrete comes in.

🍬 What Exactly Is Sugarcrete?

Think of Sugarcrete as a blend of innovation and sustainability. It’s created by mixing bagasse (the pulpy, stringy waste left after sugarcane processing) with mineral binders that help it set and harden.

Here’s why this matters:

- Agricultural waste, reimagined: Instead of dumping or burning millions of tons of sugarcane residue, which can pollute the air, we’re turning it into something useful.

- Fast-curing: Sugarcrete sets more quickly than conventional concrete, which speeds up construction.

- Energy-efficient production: Since it doesn’t require high heat to create, it consumes less energy overall.

- Locally sourced: In countries where sugarcane is abundant (think Brazil, India, Thailand, the Philippines), Sugarcrete could become a regional game-changer.

And it’s not just green. It’s tough too.

🧱 Sugarcrete vs. Concrete: The Sweet Showdown

In lab tests and early field trials, Sugarcrete has shown off some impressive traits:

| Property | Sugarcrete | Conventional Concrete |

|---|---|---|

| Weight | Up to 40% lighter | Heavy and dense |

| Compressive Strength | Comparable or better | Strong, but varies |

| Fire Resistance | Higher resistance | Moderate to high |

| Thermal Insulation | Excellent | Poor to moderate |

| Curing Time | Faster | Slower |

| Carbon Footprint | 15–20% of concrete’s | High |

That means Sugarcrete isn’t just a novelty—it could outperform concrete in critical ways, particularly in regions with limited infrastructure or resources.

In one promising project, modular floor slabs made from Sugarcrete were shown to require up to 90% less steel reinforcement than traditional concrete ones. They were also less prone to cracking—often the beginning of structural damage.

🏘️ Turning Trash into Treasure: Global Implications

To fully appreciate Sugarcrete’s potential, consider this: sugarcane is the largest crop in the world by production volume. Each year, the world harvests over 1.9 billion tons of sugarcane.

That results in hundreds of millions of tons of bagasse, most of which ends up:

- Burned, creating air pollution

- Dumped, taking up land

- Used inefficiently in low-energy applications

Now imagine taking even a fraction of that waste and transforming it into affordable housing, schools, clinics, or community centers in regions that desperately need them.

In India, for instance, rural populations could benefit from inexpensive, locally sourced Sugarcrete homes—reducing the need for imported bricks or cement. In Brazil, where sugarcane is a major industry, whole neighborhoods could be built with materials made just down the road.

🧪 Not Alone: Other Plant-Based Construction Innovations

Sugarcrete is part of a broader movement in science and architecture: using natural, renewable, and waste materials to reshape construction.

Here are a few other sweet ideas that share a similar mission:

🌿 Hempcrete

Made from the woody core of the hemp plant mixed with lime, hempcrete is:

- Lightweight

- Breathable

- Naturally insulating

It’s also carbon-negative, meaning it absorbs more CO₂ than it emits during production.

🌾 Mycelium Bricks

Engineered from fungus roots, mycelium bricks are:

- Biodegradable

- Mold-resistant

- Fire-retardant

They’ve even been used to build experimental pavilions at architectural expos.

🌾 Rice Husk Ash Concrete

In rice-producing regions, waste husks are burned to create ash that can be used as a binder in concrete mixes—reducing the reliance on cement and cutting emissions.

Like Sugarcrete, all of these innovations share one thing in common: they turn local waste into local wealth.

Read more:Injectable Hydrogel Literally Found to Increase Bone Density by Up to 5x, Study Shows

🛠️ The Future of “Living” Materials: Enter Self-Healing Concrete

Beyond using sustainable ingredients, scientists are exploring how building materials can become more resilient and self-sufficient.

That’s where self-healing concrete comes in.

This sci-fi-sounding material is laced with bacteria or tiny capsules that stay dormant until a crack appears. When moisture enters the crack:

- Bacteria activate and start producing limestone, sealing the gap.

- Capsules rupture and release repair agents, filling and fixing the damage.

Imagine roads, bridges, or buildings that automatically heal themselves after small damage, drastically cutting down on repair costs and extending their lifespans.

Together with innovations like Sugarcrete, these materials point toward a new generation of architecture: smarter, greener, longer-lasting.

🏗️ Sweet, Strong, and Sustainable: What Comes Next?

While Sugarcrete is still in its early stages, pilot projects and prototypes are being explored in real-world settings. The next step is scaling up production, improving durability for long-term use, and refining local supply chains to make it cost-competitive everywhere.

Possible applications include:

- Rural homes and schools

- Disaster relief shelters

- Public infrastructure in tropical regions

- Low-carbon architectural projects in cities

Architects, builders, and sustainability advocates are already paying attention. Universities, especially in sugar-producing nations, are beginning to study the material more deeply. With growing awareness of climate risks and resource scarcity, Sugarcrete could quickly move from novelty to necessity.

🌎 Final Thoughts: Building a Sweeter Future

What began as agricultural waste may soon be the cornerstone of sustainable cities. Sugarcrete shows that the future of housing doesn’t have to be built on sand, steel, and smog—it can grow from the ground up, quite literally.

It’s not just a clever use of waste. It’s a vision of what construction could become when we let nature and science collaborate: cleaner, smarter, and sweeter.

So the next time you stir a spoonful of sugar into your coffee, consider this: the leftovers from that sugar might someday help build a home, a school, or even a city. Now that’s a future worth chewing on.

News in the same category

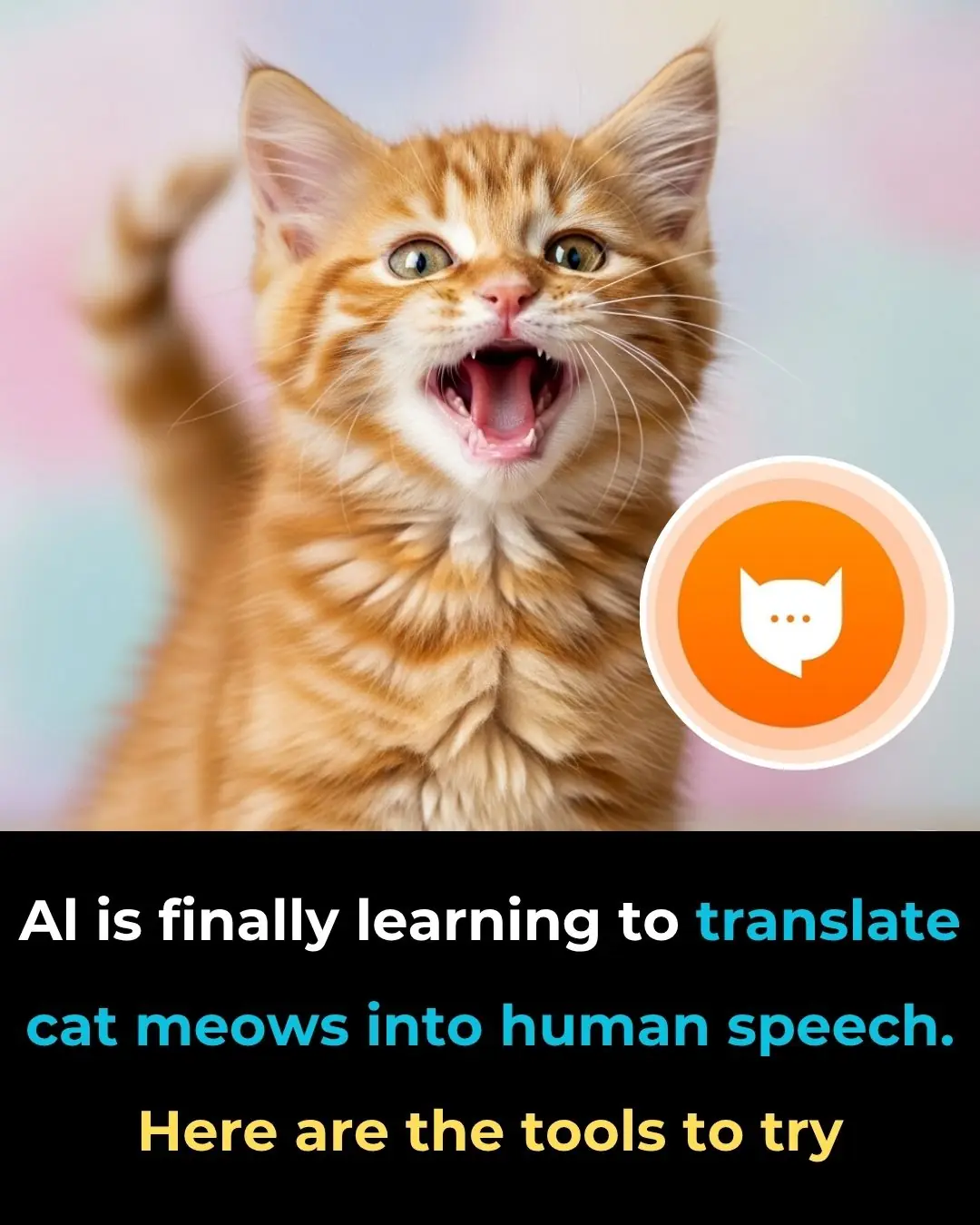

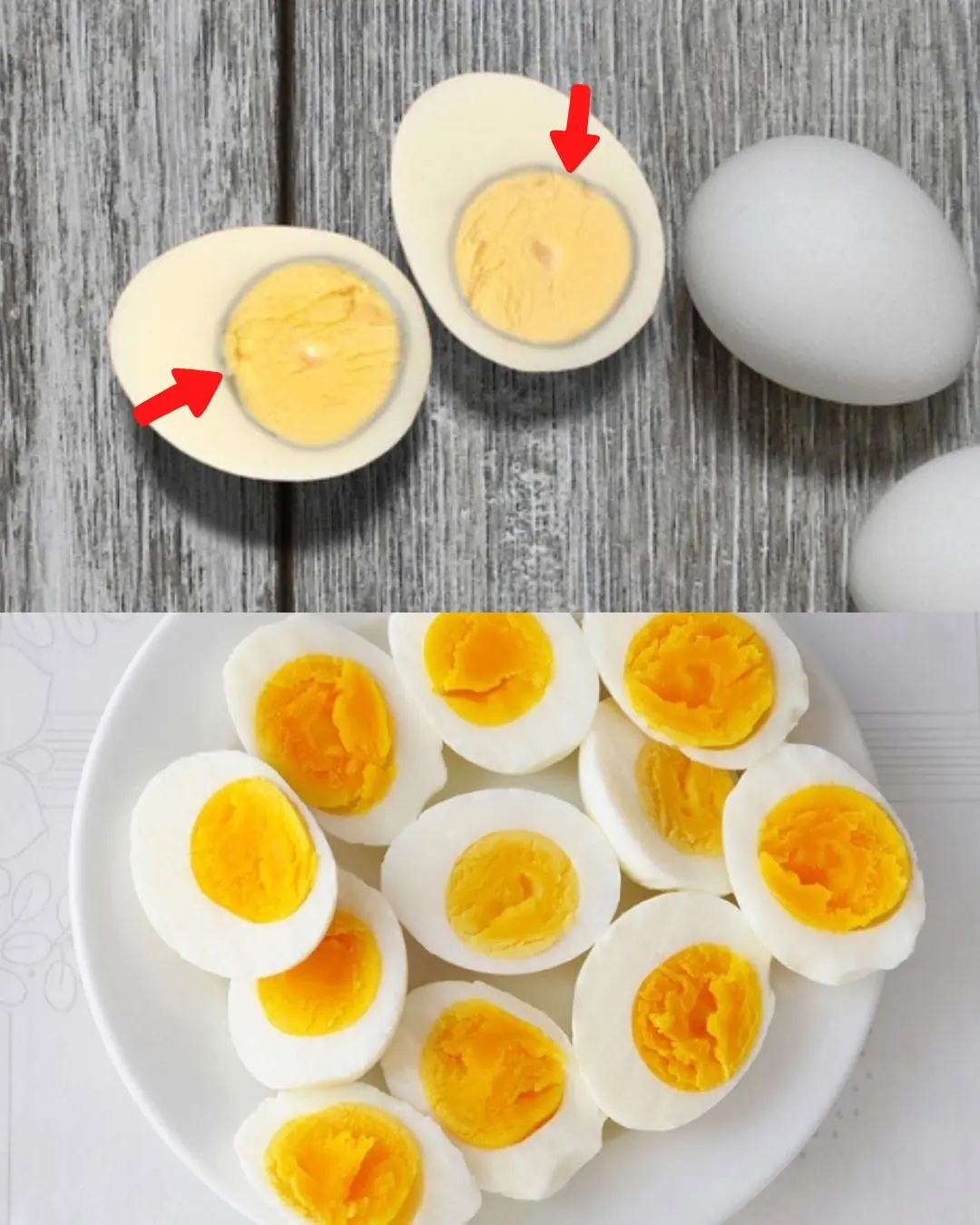

What causes the green ring around hard-boiled eggs?

Scientists Say More Animals Are Conscious Than We Ever Imagined—Even Insects

5 foods you should never keep overnight

63 Earths Can Fit Comfortably Inside Uranus

Mom Tells Boy He Can Pick Any Animal At Shelter. He Picked This Eldery, Overweight And Shy Cat

A New Study Suggests We Might Be Sitting Inside a Huge Cosmic Void and That Could Solve One of the Biggest Puzzles in Cosmology

What Your Ankle Bracelet Really Says About You — It’s More Than Just Jewelry

Scientists Turn Coffee Waste Into Bricks—And They’re Twice as Strong as Standard

The Amount of Electricity Now Being Generated From Solar Is Unbelievable

Scientists Turn Coffee Waste Into Bricks—And They’re Twice as Strong as Standard

Study Reveals Reading is a Complex, Flexible Brain Process Involving Multiple Interacting Neural Networks

Australia Is Using 3D Printers To Save Coral Reefs, And The Fish Are Already Moving In

Planet Earth Has Been Spinning Faster Lately

Goodbye Nursing Homes! The New Trend Is CoHousing With Friends

Global warming could permanently shift rainfall patterns, affecting water access for 2 billion people worldwide, study shows.

The Amount of Electricity Now Being Generated From Solar Is Unbelievable

Scientists Discover Cosmic Glitch That Challenges Everything We Know About Gravity—And May Mean Our Universe Is an Illusion

The Reason Dogs Chase People? Causes And Care Tips From A Vet

News Post

AI is Finally Learning to Translate Cat Meows Into Human Speech. Here Are the Tools to Try

What causes the green ring around hard-boiled eggs?

Scientists Say More Animals Are Conscious Than We Ever Imagined—Even Insects

5 foods you should never keep overnight

63 Earths Can Fit Comfortably Inside Uranus

Mom Tells Boy He Can Pick Any Animal At Shelter. He Picked This Eldery, Overweight And Shy Cat

A New Study Suggests We Might Be Sitting Inside a Huge Cosmic Void and That Could Solve One of the Biggest Puzzles in Cosmology

Proven Health Benefits of Celery & Nutritional Facts (Evidence-Based)

Mold Illness: What It Is, Hidden Signs, and How to Protect Your Home

80% of Heart Attacks Are Preventable: Embrace These 5 Simple Habits

Is Cancer Hereditary? Helpful Tips to Prevent the Growth of Cancer Cells

Warning from Hospitals: Eating This Type of Meat Every Day Can Increase Cancer Risk – Don’t Be Complacent!

3 Pain Areas on the Body That Could Signal Early-Stage Cancer: Don’t Delay, or It Could Spread

What Your Ankle Bracelet Really Says About You — It’s More Than Just Jewelry

Truth behind viral statement after married CEO caught with employee on Coldplay kiss cam

DIY Okra Face Gel Recipe for Radiant, Firm Skin: Collagen Boosting Skincare Solution for Glowing Skin

By incorporating this okragel into your nightly skincare routine, you can enjoy smoother, firmer, and more radiant skin in just a few simple steps.

Homemade Rice Face Cream: A Simple, Natural Skincare Solution to Achieve Radiant Glass Skin in 7 Days

It’s time to create the DIY rice face cream that will help you achieve glowing, glass-like skin in just 7 days.

Natural Solutions for Gout: Tackling Uric Acid to Prevent Pain