Turning Grass Into Paper: Wageningen Researchers Create Sustainable Alternative to Wood Pulp

Turning Grass Into Sustainable Paper and Cardboard

Researchers in Wageningen University are pioneering an innovative method to convert grass harvested from road verges, parks, and nature reserves into paper and cardboard. By using locally sourced grass instead of imported wood pulp, this approach reduces dependence on long supply chains and helps support regional economies. The benefits extend beyond supply chain improvements: using grass as a raw material cuts transportation costs, lowers carbon emissions, and alleviates the ecological pressure on forests, which are often threatened by large-scale logging for paper production. Environmental experts from European Forest Institute note that alternatives to wood-based pulp are crucial to reducing global deforestation and protecting biodiversity.

Advanced Sorting and Processing Techniques

The Wageningen system employs advanced technology to ensure the raw grass is suitable for papermaking. Trained cameras and optical sensors detect and remove metal, plastic, and other contaminants before the grass enters the processing line. This pre-cleaning step is vital, as foreign materials can damage machinery and reduce product quality. Following this, the grass undergoes a sequence of steps including washing, shredding, and fiber extraction to produce a pulp that meets industrial standards. According to researchers from Fraunhofer Institute for Process Engineering and Packaging IVV, this method not only produces high-quality pulp but also dramatically reduces water and chemical usage compared to traditional wood-based processes.

Reduced Environmental Footprint

Using grass as a raw material offers several environmental advantages. The process requires far less water and fewer bleaching agents, minimizing chemical discharge into waterways. Additionally, the energy footprint is lower because grass fibers are easier to break down than woody fibers, reducing the amount of mechanical and thermal energy needed during processing. Studies from International Paper Research Institute suggest that integrating alternative fibers like grass into papermaking could cut water consumption by up to 50% and chemical usage by 40% relative to conventional wood pulp production.

Creating Value From Waste

Grass collected from verges, parks, and nature reserves is often considered waste and is typically left to decompose or burned, releasing greenhouse gases. By converting it into a usable raw material, researchers are creating a new revenue stream from an otherwise discarded resource. This approach exemplifies circular economy principles by transforming organic waste into high-value products. Analysts from Ellen MacArthur Foundation emphasize that such strategies are vital for sustainable industrial practices and reducing pressure on natural ecosystems.

Implications for the Paper Industry

This innovation demonstrates that paper and cardboard production can move toward more sustainable and localized raw materials without compromising quality. European universities and research institutes continue to investigate integrating grass and other non-wood fibers into industrial pulp mills. The Wageningen project provides concrete evidence that grass-based pulp is not only feasible but scalable, offering a viable path to reduce dependence on imported wood and improve the environmental footprint of the paper industry.

By combining smart technology, local resource utilization, and environmentally conscious processing, this initiative shows how discarded biomass can become a valuable asset while supporting sustainable industrial development. It represents a promising step toward greener, more resilient supply chains for paper and cardboard production.

News in the same category

Why Sleeping Naked May Boost Your Sleep, Skin Health, and Metabolism

Why You Should Be Putting Salt in Your Toilet

Why Some Children Don’t Visit Their Parents Often

Will Americans Receive $2,000 Stimulus Checks? What You Need to Know

14 Reasons to Drink Lemon Water First Thing in the Morning

Meet the Owners Behind Baltimore’s First Black & Woman-Owned Bodega

Quinta Brunson to Receive Keys to Hometown City of Philadelphia

Bethann Hardison & Andrew J. Young Honored at Gordon Parks Foundation Gala

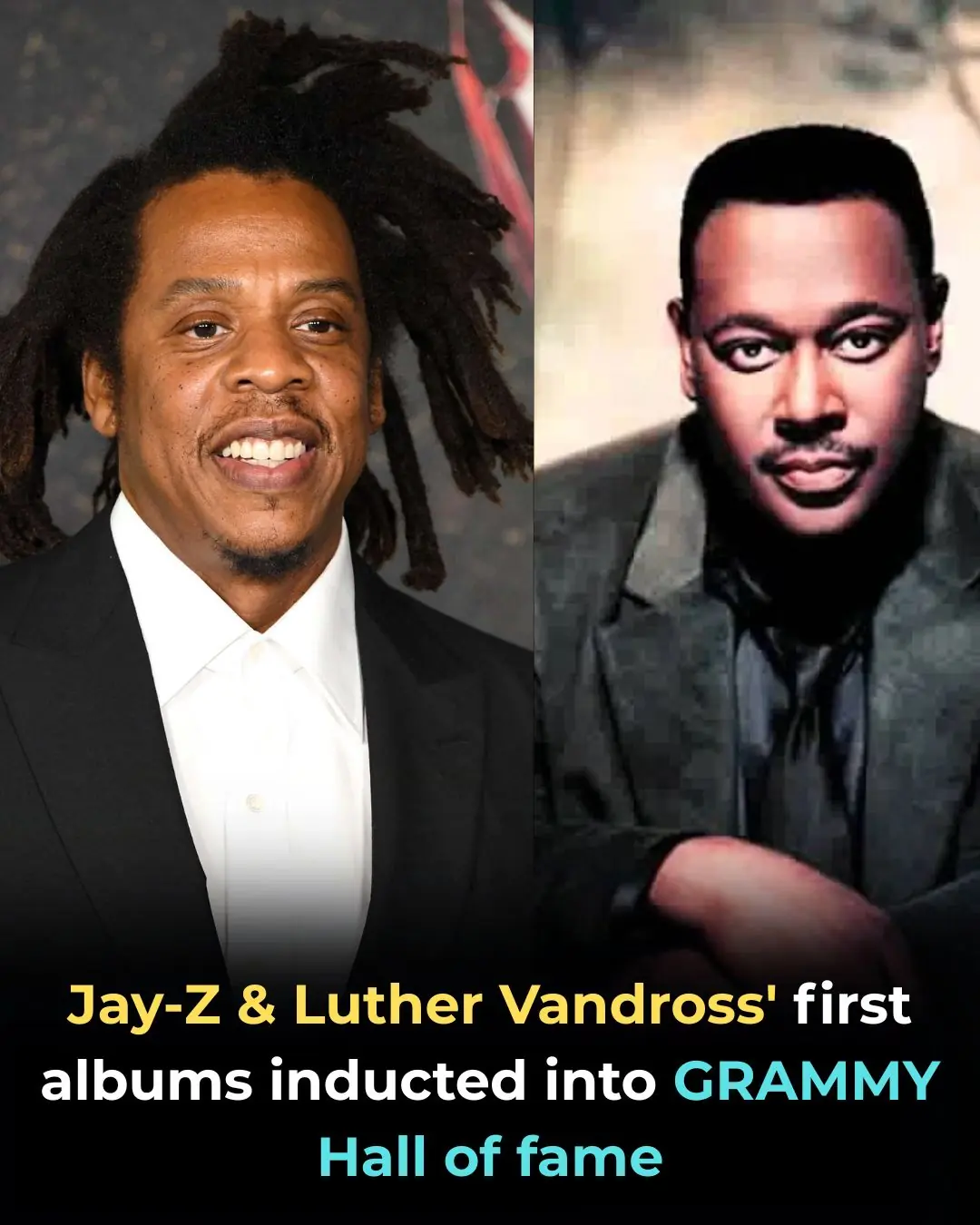

Jay-Z & Luther Vandross’ First Albums Inducted Into GRAMMY Hall of Fame

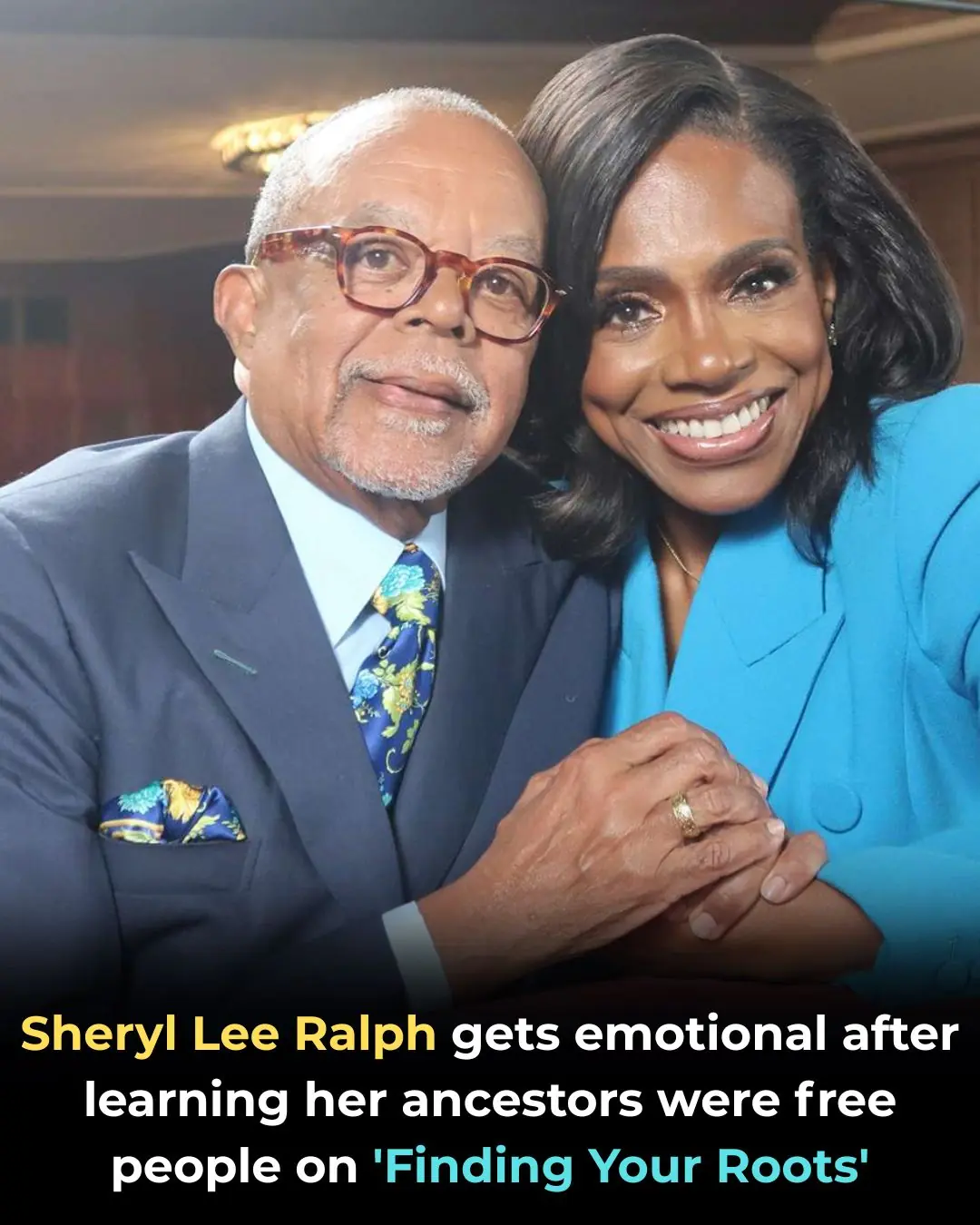

Sheryl Lee Ralph Gets Emotional After Learning Her Ancestors Were Free People on ‘Finding Your Roots’

Philadelphia Entrepreneur Becomes The First Queer Black Woman To Lead A Biopharmaceutical Manufacturing Company

‘Tia Don’t Piss Me Off’: Tia Mowry’s Selfie with Mystery Man Has Folks Noticing He Looks Nothing Like Ex Cory Hardrict Despite Reunion Chatter

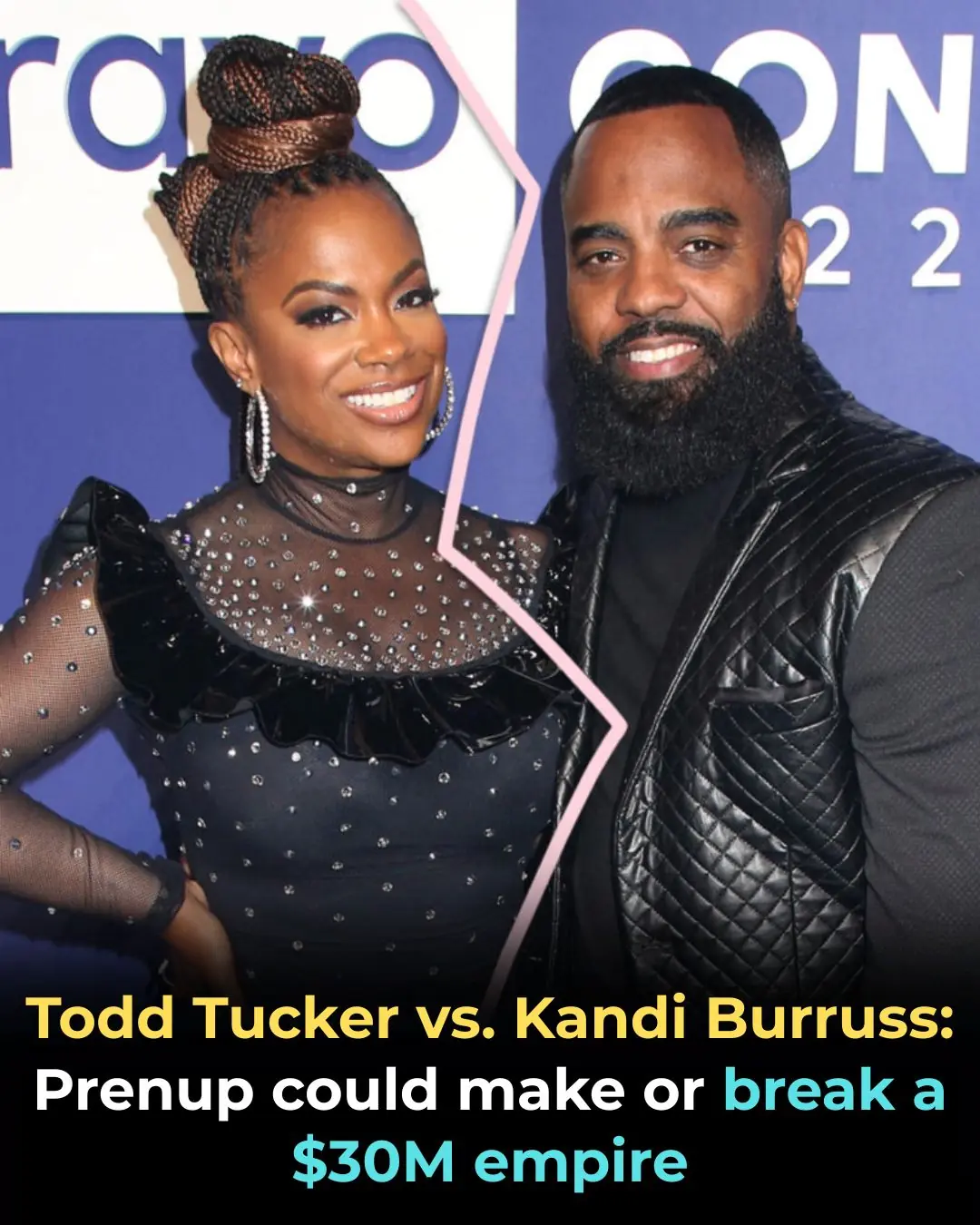

Todd Tucker vs. Kandi Burruss: Prenup Could Make or Break a $30M Empire

HBCU Grad Rajah Caruth Secures Second Career NASCAR Truck Series Win

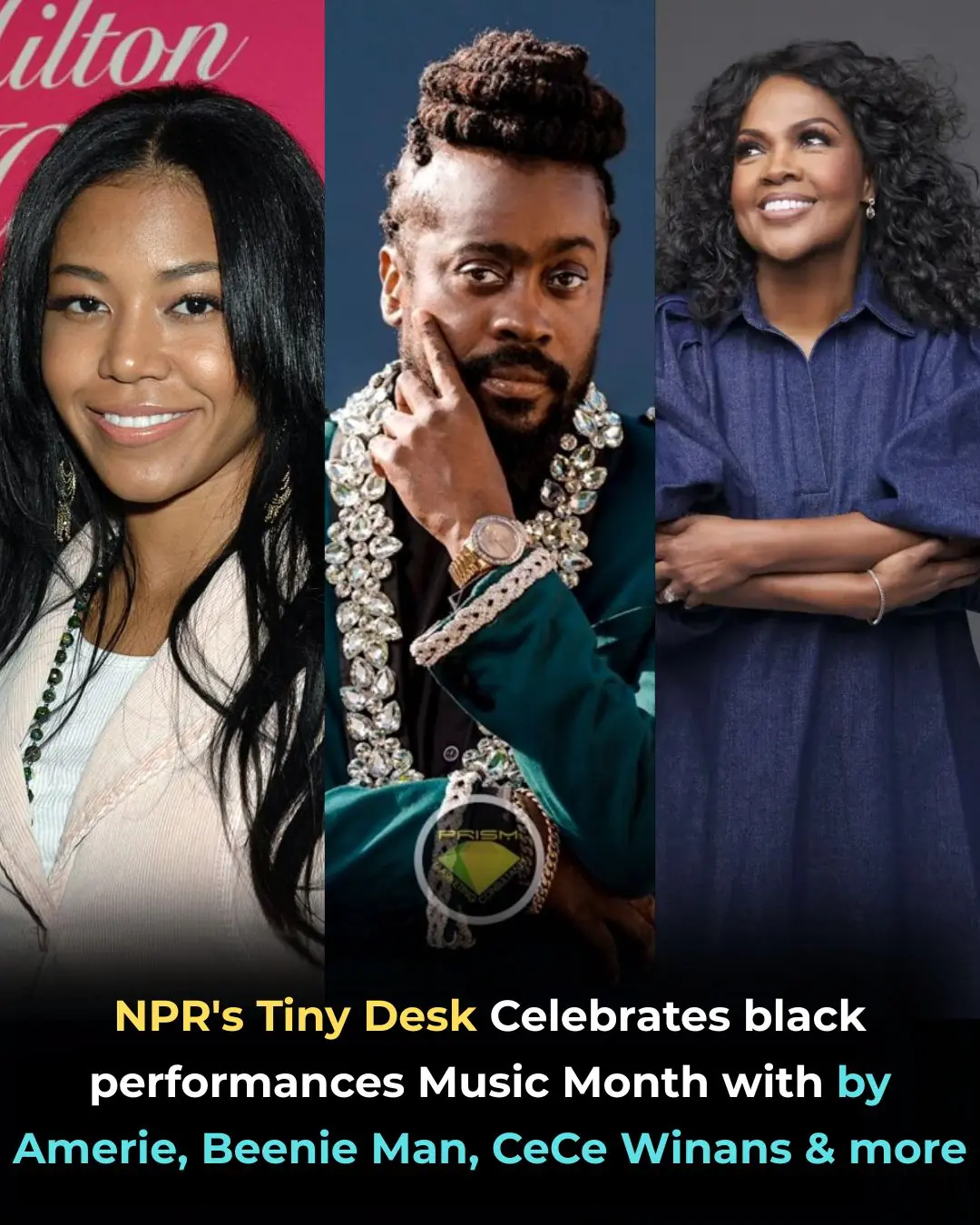

NPR’s Tiny Desk Celebrates Black Music Month With Performances by Amerie, Beenie Man, CeCe Winans & More

Tiffany Derry Makes History as MasterChef’s First Black Full-Time Judge

Kwame Onwuachi to Open New Restaurant ‘Maroon,’ the First Black Chef-Led Restaurant on the Las Vegas Strip

How Artists and Engineers Are Confusing Facial Recognition AI

News Post

1 teaspoon a day melts away fatty liver naturally

Solar-Powered Tesla Experiment Proves Off-Grid Charging Is Possible

Why Sleeping Naked May Boost Your Sleep, Skin Health, and Metabolism

The Girl Who Brought Graduation to the Jailhouse Door.

The Last Walk — A Love That Refused to Let Go.

The Race She Never Got to Run.

He Refused to Leave the OR — Even After 16 Hours Off the Clock.

Lunch for Three: A Soldier, a Widow, and the Man Who Still Lives at the Table.

THE LITTLE GIRL AND THE ELEPHANT WHO THANKED HER.

Mix rice with this and leave it in the corner of the house, it will wipe out all the rats overnight.

When choosing a cantaloupe, use these 4 tips to ensure you buy one with thin skin and sweet flesh.

High Blood Pressure Has a New Culprit …And It’s Not Salt

Top 5 drinks to INSTANTLY improve leg circulation and blood flow

Doctor says this is the #1 supplement to take if you have arthritis

Why Your Legs Cramp At Night And How To Stop It From Happening

What happens when you start eating chia seeds every day

The Plant That Kills Cancer Cells, Stops Diabetes And Boosts Your Immune System!

How to treat nerve pain in the foot, toes & legs