Why Do Flat Electrical Plugs Have Two Round Holes? The Hidden Function Is Brilliant

Have you ever noticed that flat electrical plugs often have two small round holes on their metal prongs and wondered why?

Every detail in a household product—especially something as essential as an electrical plug—is designed with careful thought to improve convenience, safety, and efficiency for users.

The Primary Purpose: A More Secure Connection

The first and most important purpose of the two small holes is to make the plug fit more securely into the socket. Inside most standard outlets, there are small raised bumps or catches designed to fit perfectly into these holes.

When the prongs slide in, the bumps “lock” into the holes, ensuring that the plug stays firmly in place and doesn’t slip out easily. This design helps maintain a stable electrical connection, reducing the risk of flickering power or short interruptions when the plug is moved slightly.

Added Safety Benefits

These holes are also about safety. By allowing a more stable fit, they minimize the chance of exposed metal when the plug is partially inserted—an especially important feature in households with children. Some modern outlets also include safety shutters or mechanisms that engage with the holes, preventing children from inserting fingers or metal objects and getting an electric shock.

Without these holes, plugs can become loose or wobbly over time, creating small gaps where electrical arcing might occur—tiny sparks that can be dangerous if flammable materials are nearby.

From Early Design to Modern Perfection

In the early days of electrical plug design, manufacturers used small indentations instead of holes. These indentations helped hold the plug in place but caused increased friction when inserting or removing the plug, sometimes producing small electric arcs or sparks.

Over time, engineers replaced the indentations with clean round holes, which not only improved safety but also made plugging and unplugging smoother. The idea was originally introduced by Harvey Hubbell Jr., an American inventor credited with many innovations in plug design. His early models evolved into the standard Type A and Type B plugs that are still in use today.

Efficiency and Manufacturing Advantages

Another clever aspect: adding holes helps manufacturers save a small but significant amount of metal. While it may seem like a tiny reduction, when you produce millions of plugs, even a slight material saving translates into substantial cost and resource efficiency.

Additionally, many manufacturers use the holes to attach security seals or labels—a way to ensure product authenticity and prevent counterfeiting in the market.

Global Standards and Variations

Today, the Type A plug (two flat blades) and Type B plug (two flat blades and a round grounding pin) are common in countries like the United States, Canada, and Japan. These designs follow the NEMA (National Electrical Manufacturers Association) standards.

In contrast, many European and Asian countries use round-pin plugs, which fit snugly into matching round sockets. Because of their natural grip and contact pressure, these plugs don’t need extra holes—the circular shape already ensures a strong, stable connection.

More Than Just Two Small Holes

So, those tiny holes on your flat plug aren’t just random details—they represent a century of thoughtful engineering. They help your plug stay secure, improve electrical contact, enhance safety, reduce manufacturing costs, and even assist with product verification.

The next time you plug in your charger or appliance, take a second look at those little holes. Behind them lies a smart and simple piece of design that makes everyday life a bit safer and more efficient.

News in the same category

You’re doing it all wrong. Here’s the right way to store eggs

The reasons why public toilet doors don't touch the ground.

Pouring Salt into the Toilet: Everyone Thinks It’s Crazy, but Once You Know Its Benefits, You’ll Try It at Home Immediately

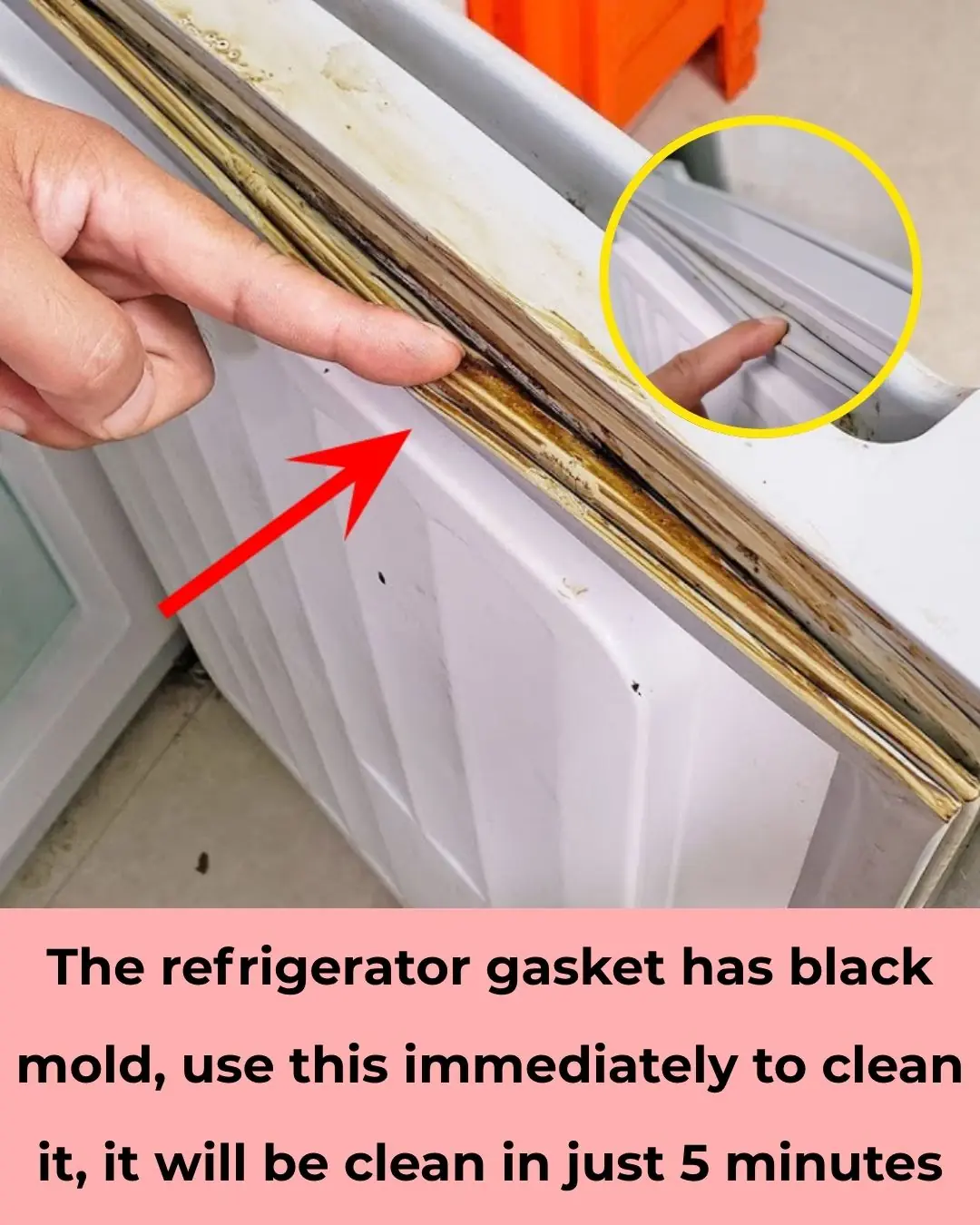

Black Mold on Refrigerator Seals? Use This Trick to Clean It in Just 5 Minutes

Don’t Ignore This: Check Your Fridge Now and Remove These 7 Items Before It’s Too Late

Why is that and the answer for those who don't know?

What Your Pile of Dirty Dishes Might Really Be Saying About You

You're doing it all wrong. Here’s the right way to store butter

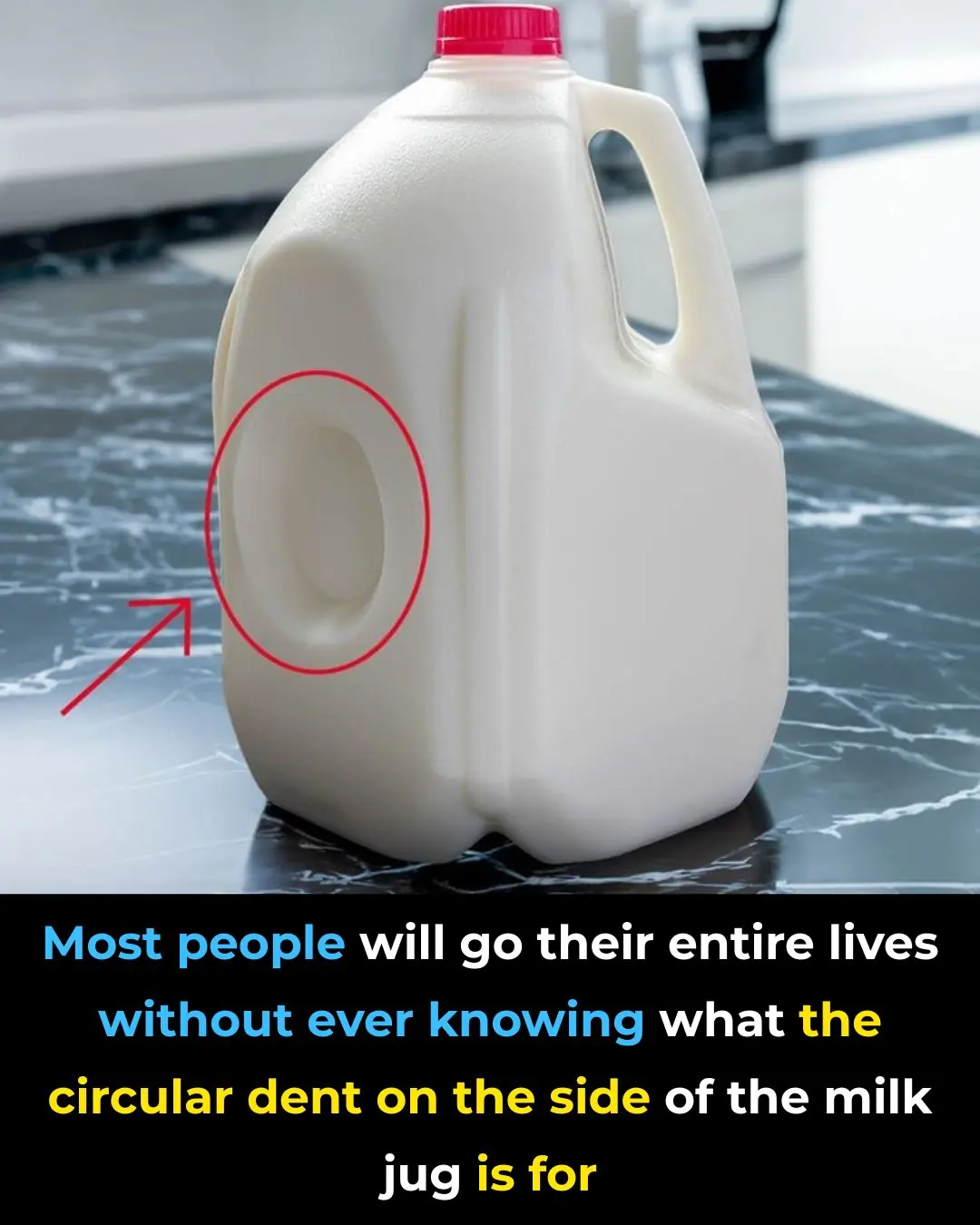

Why There’s a Dent in Your Milk Jug—and What It Actually Does

The more you clean a leaky house, the dirtier it gets: Do this to dry it, with immediate effect

During humid spring rains, put this in the bathroom to help deodorize, avoid moisture, and save cleaning time.

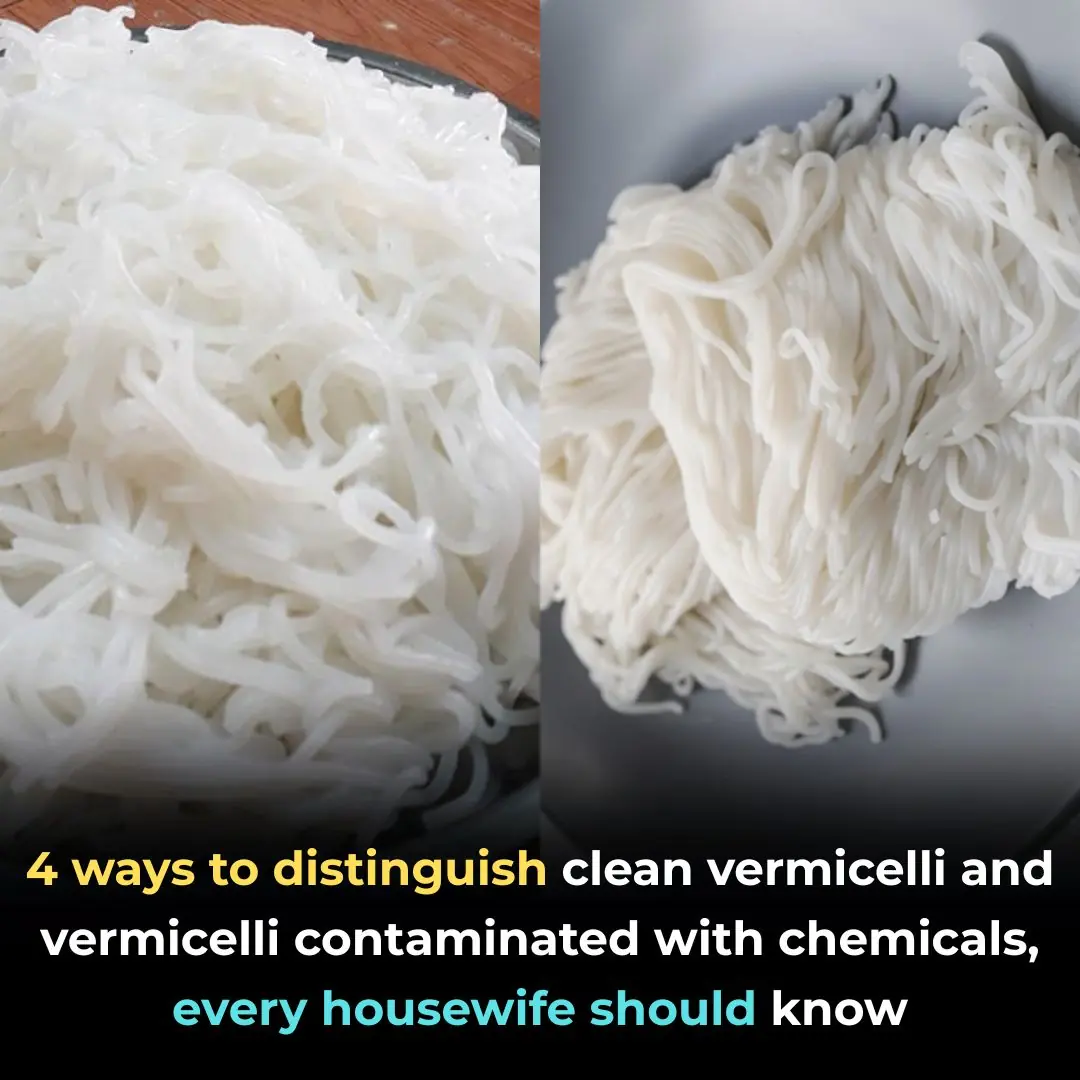

4 ways to distinguish clean vermicelli and vermicelli contaminated with chemicals, every housewife should know

Tips for salting white eggplants so they stay crunchy, don't turn black, and don't develop mold over time

Putting citrus peels in white vinegar helps solve many household problems without wasting effort.

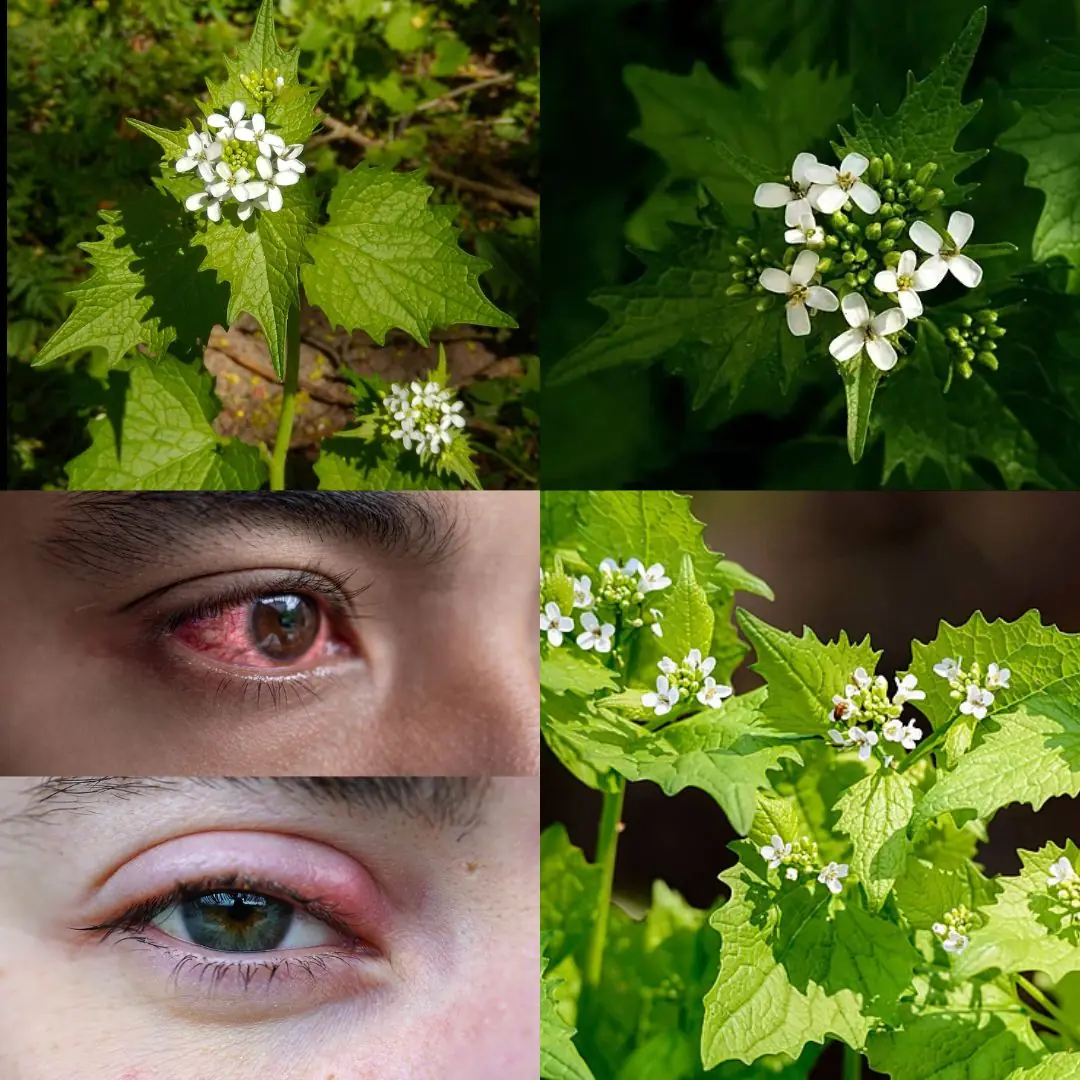

The whole world values this type of fruit even more than cordyceps; Vietnam has plenty of it, but no one knows to eat it.

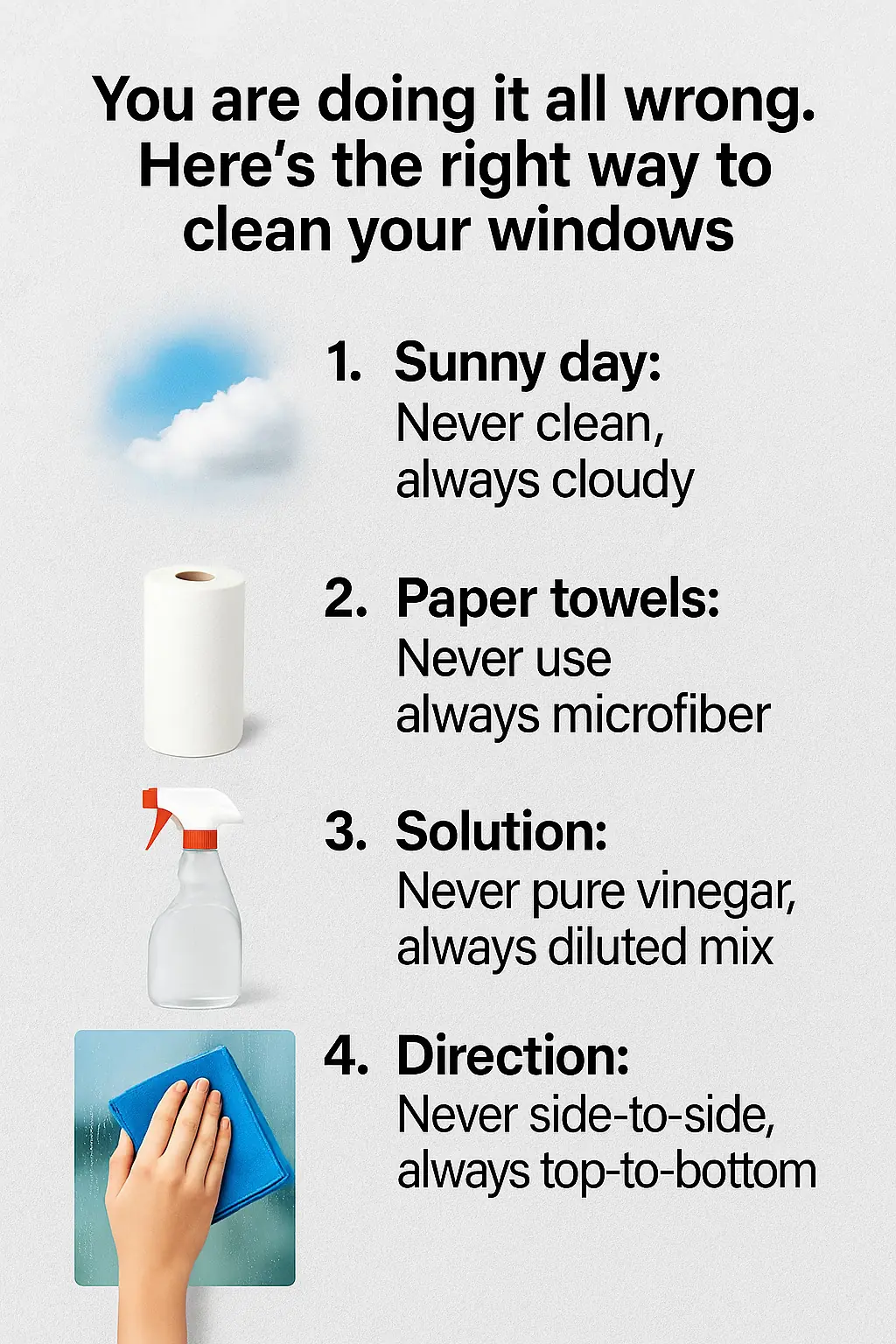

You are doing it all wrong. Here's the right way to clean your windows

My nana taught me this hack to whiten dingy grout in 4 mins with 0 work. Here’s how it works

You’re doing it all wrong. Here’s the right way to dust your home

News Post

5 Amazing Benefits Of Aloe Vera Gel For Skin: Large Pores, Dark Spots, Wrinkles

Clove & Lemon Collagen Drink: Wrinkle Free, Glowing Skin

Unlock Your Body’s Hidden Power: Try Garlic and Honey on an Empty Stomach for 7 Days

Tragus Piercing What Does It Mean

9 Health Benefits of Pine Needles

Unlock The Incredible Health Benefits of Garlic, Ginger and Lemon for Men

A special method to grow garlic in plastic bottles

7 Benefits of the Miracle Leaf of Life

7 Amazing Health Benefits of Banana Blossoms

Boiling Sweet Potatoes: Don’t Just Add Plain Water—Add This Spoonful for Perfectly Fluffy, Sweet Results

The Science Behind Putting a Cotton Swab in a Menthol Oil Bottle

More People Are Struggling with Visceral Fat — Doctors Reveal 9 Foods That Help Burn It Naturally

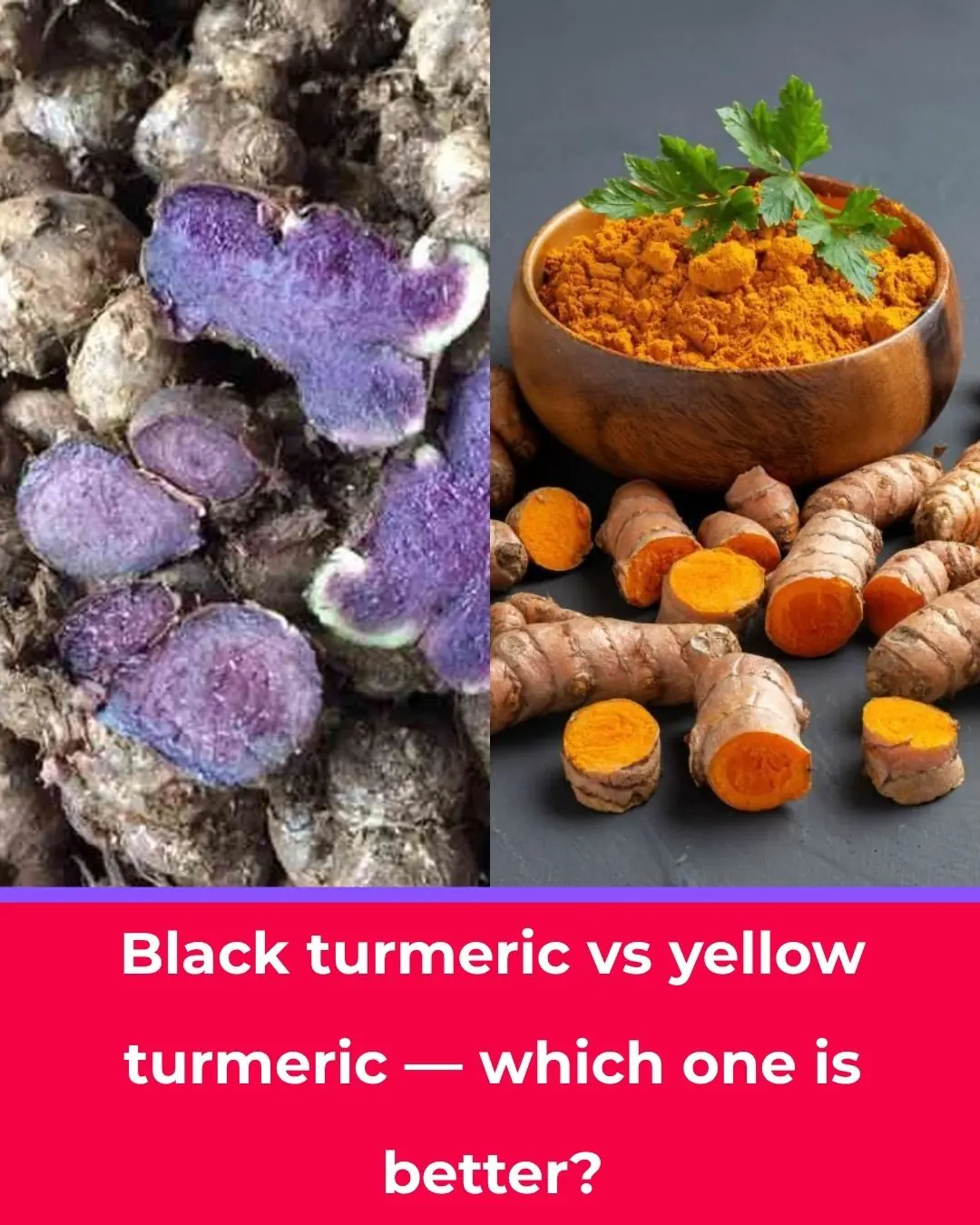

Black Turmeric vs. Yellow Turmeric: Which One Is Better?

Starve cancer: the diet rotation strategy you need to know

Like to see more from Tips for the Home

💪 Sarcopenia: Why Muscle Loss Happens & How to Fight It (After 50)

I Had No Idea About This!

These Ideas Are Amazing: 10 Clever Ways to Use Dryer Sheets Beyond the Laundry Room

Most Don’t Know: 13 Brilliant Ways to Use WD-40 Around the House