Why There’s a Dent in Your Milk Jug—and What It Actually Does

Every morning, many of us reach into the fridge, grab that familiar plastic milk jug, and pour a splash into our coffee or cereal. But have you ever stopped to notice the small circular dent on the side of the jug? It might look like a manufacturing flaw, but it’s actually a subtle piece of engineering brilliance — one that keeps your milk fresh, your jug sturdy, and your refrigerator clean.

The Real Purpose of the Circular Dent

That little indentation isn’t just for looks or easy gripping. It’s a pressure-regulating feature, carefully designed to help your milk jug adapt to temperature changes and physical stress.

1. A Built-In Pressure Release System

Milk, like any liquid, expands and contracts as temperatures fluctuate:

-

When cold, both the milk and the air inside the jug shrink slightly.

-

When warm, they expand.

Without that dent, these shifts could make the jug bulge outward or even burst. The circular indentation acts as a flexible “breathing zone,” expanding or contracting to absorb pressure changes and maintain balance — preventing leaks or structural failure.

Think of it like a safety cushion that keeps the jug stable no matter what the fridge (or the weather) throws at it.

2. Reinforcing the Jug’s Structure

The dent also doubles as a structural support — a kind of shock absorber built right into the plastic. It:

-

Distributes pressure evenly across the jug’s surface.

-

Helps prevent the thin plastic walls from caving in.

-

Allows manufacturers to use lighter, more sustainable materials.

Ever pressed on that dent and felt it pop in or out? That’s intentional flexibility, not weakness. It’s proof the design is working exactly as planned.

From Glass Bottles to Plastic Marvels: The Evolution of Milk Containers

Long before the age of plastic, milk was sold in glass bottles — heavy, fragile, and costly to transport. In the 1950s and ’60s, producers began switching to HDPE (high-density polyethylene), a strong yet lightweight plastic that revolutionized packaging.

But early plastic jugs weren’t perfect. They had a few problems:

-

They expanded too easily when exposed to warmth.

-

They sometimes buckled under transport stress.

-

Leaks and split seams were common.

Engineers solved these issues by introducing the circular dent — a tiny tweak with massive impact. This flexible feature allowed jugs to withstand internal pressure changes without cracking, making milk safer to store, ship, and stack. Over time, it even reduced the amount of plastic needed, cutting costs and waste.

The Science Behind the Dent

Milk jugs are made using a process called blow molding, where molten plastic is inflated inside a mold until it takes shape. During this process, the dent is intentionally molded into the jug to control internal stress and pressure variations.

The dent’s functions include:

-

Absorbing expansion when milk warms and internal pressure rises.

-

Contracting safely when the contents cool and pressure drops.

-

Reinforcing the structure, thanks to its curved dome shape.

In simple terms, the dent allows the jug to “breathe” — flexing without cracking, a perfect marriage of science, practicality, and design.

Why the Dent Pops In or Out

If you’ve ever noticed that the dent sometimes changes shape, that’s the jug’s self-adjusting mechanism in action.

-

When cold, the dent pulls inward as the air inside contracts.

-

When warm, it pushes outward as pressure increases.

This constant adjustment keeps the jug’s walls stable, preventing unsightly bulges or messy leaks. It’s the same principle used in carbonated drink bottles — but here, it’s optimized for non-pressurized liquids like milk, juice, and water.

Hidden Roles: Transportation, Sustainability, and Safety

The circular dent isn’t just about temperature regulation. It also plays a vital role in transportation efficiency and environmental sustainability.

Here’s how it helps:

-

Prevents cracks and leaks during long-distance shipping.

-

Allows the use of thinner plastic without sacrificing strength.

-

Improves recyclability and reduces total plastic waste.

Thanks to continuous refinements in design, the average milk jug today weighs about 60 grams, nearly half the weight of those used 30 years ago. That may sound small, but across millions of gallons of milk, it translates to thousands of tons of plastic saved each year.

Beyond Milk: Where Else You’ll See It

Once you start paying attention, you’ll notice similar dents and curves on many everyday containers, including:

-

Juice and iced tea bottles

-

Cooking oil jugs

-

Household cleaning products

In every case, the principle remains the same — smart design that balances strength, flexibility, and material efficiency.

Everyday Engineering Genius

This simple dent is a perfect example of “form follows function.” It turns an ordinary household object into a quiet masterpiece of engineering. The milk jug’s design is human-centered — reliable, cost-effective, and so well-integrated that most of us never think twice about it.

Bonus: The Dent as a Freshness Indicator

Here’s a clever bonus feature: the dent can sometimes signal if your milk has gone bad.

If the circular area bulges outward more than usual, it could mean gas is building up inside — a sign that bacteria are multiplying and the milk is spoiling. It’s a simple, built-in warning system that helps you spot a problem before you open the lid.

Final Thoughts

That tiny circular dent on your milk jug does far more than you might imagine. It:

-

Balances internal air pressure

-

Strengthens the jug’s structure

-

Prevents spills, cracks, and leaks

-

Enables lighter, eco-friendly materials

-

Even offers a visual freshness check

So next time you pour a glass of milk, take a second to appreciate that small dent. It’s a quiet reminder that even the simplest everyday objects can embody decades of innovation, science, and thoughtful human design.

News in the same category

You’re doing it all wrong. Here’s the right way to store eggs

The reasons why public toilet doors don't touch the ground.

Pouring Salt into the Toilet: Everyone Thinks It’s Crazy, but Once You Know Its Benefits, You’ll Try It at Home Immediately

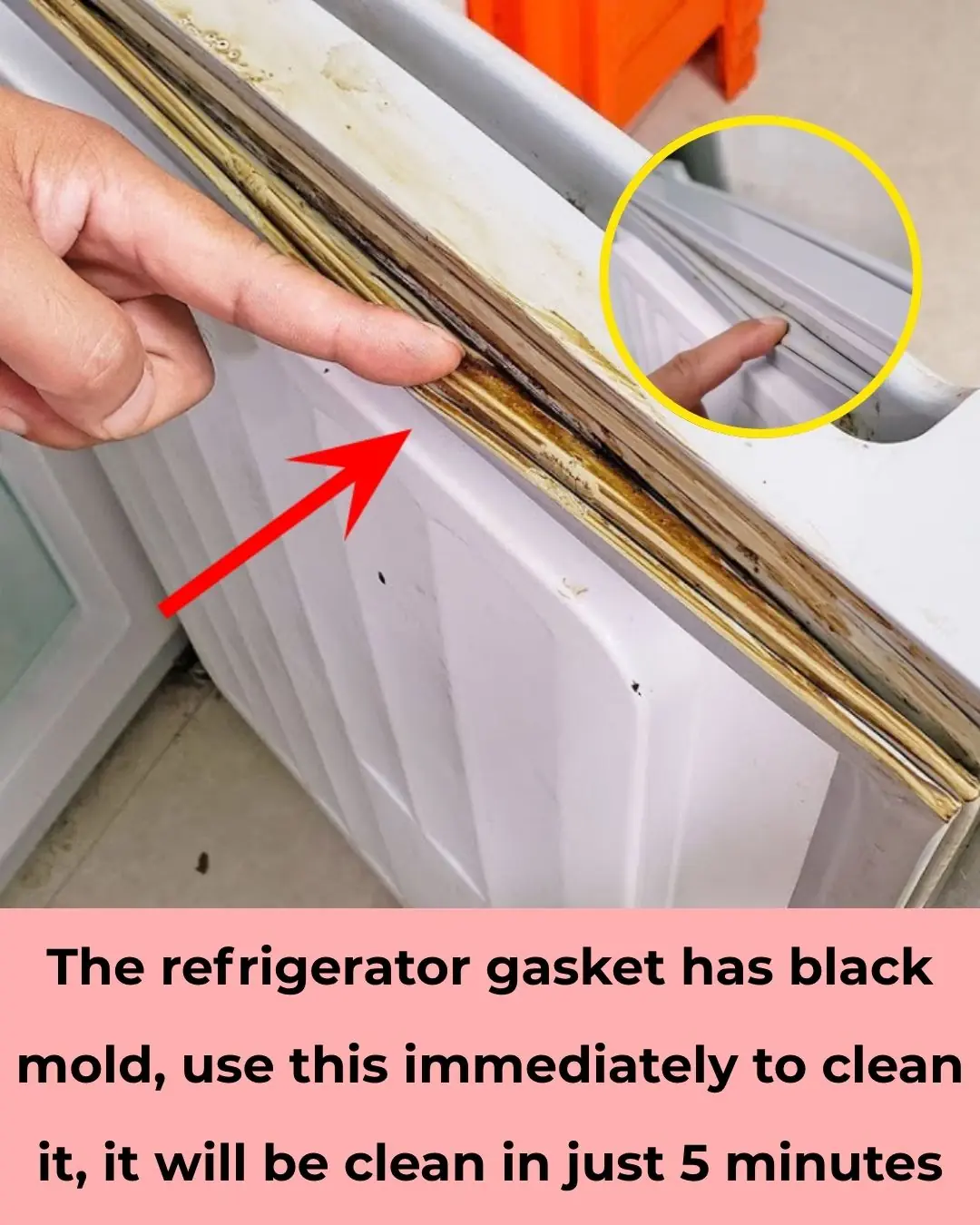

Black Mold on Refrigerator Seals? Use This Trick to Clean It in Just 5 Minutes

Don’t Ignore This: Check Your Fridge Now and Remove These 7 Items Before It’s Too Late

Why is that and the answer for those who don't know?

Why Do Flat Electrical Plugs Have Two Round Holes? The Hidden Function Is Brilliant

What Your Pile of Dirty Dishes Might Really Be Saying About You

You're doing it all wrong. Here’s the right way to store butter

The more you clean a leaky house, the dirtier it gets: Do this to dry it, with immediate effect

During humid spring rains, put this in the bathroom to help deodorize, avoid moisture, and save cleaning time.

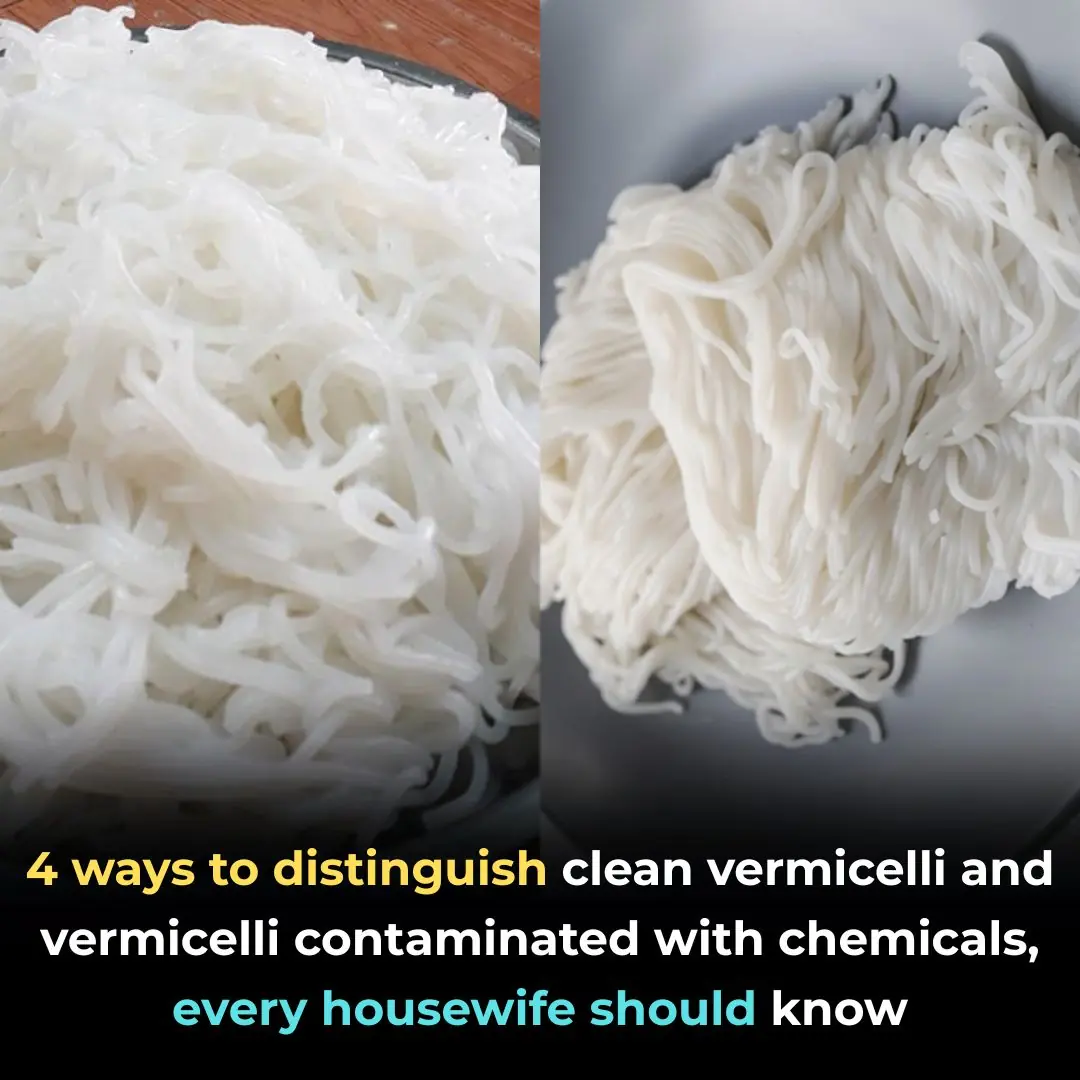

4 ways to distinguish clean vermicelli and vermicelli contaminated with chemicals, every housewife should know

Tips for salting white eggplants so they stay crunchy, don't turn black, and don't develop mold over time

Putting citrus peels in white vinegar helps solve many household problems without wasting effort.

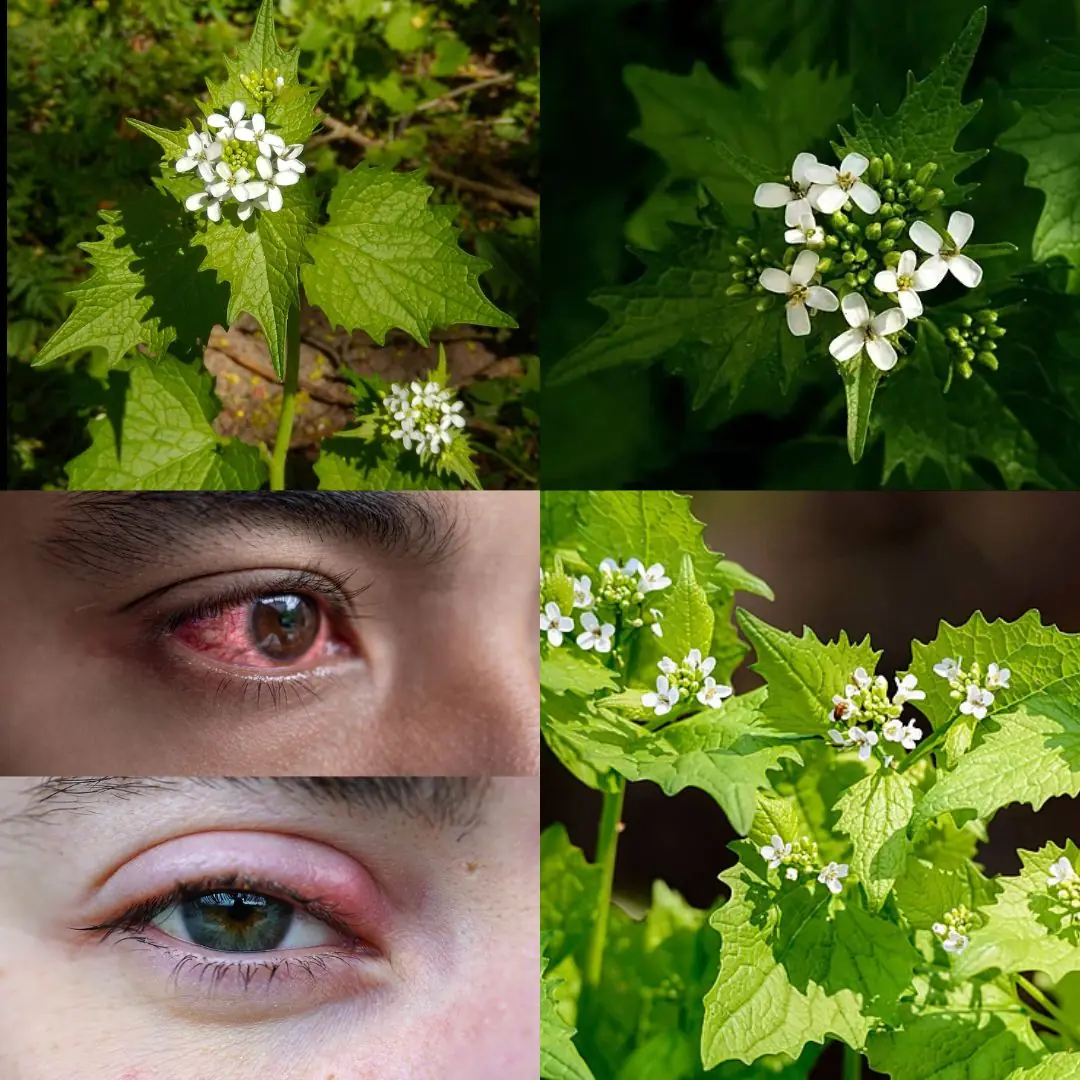

The whole world values this type of fruit even more than cordyceps; Vietnam has plenty of it, but no one knows to eat it.

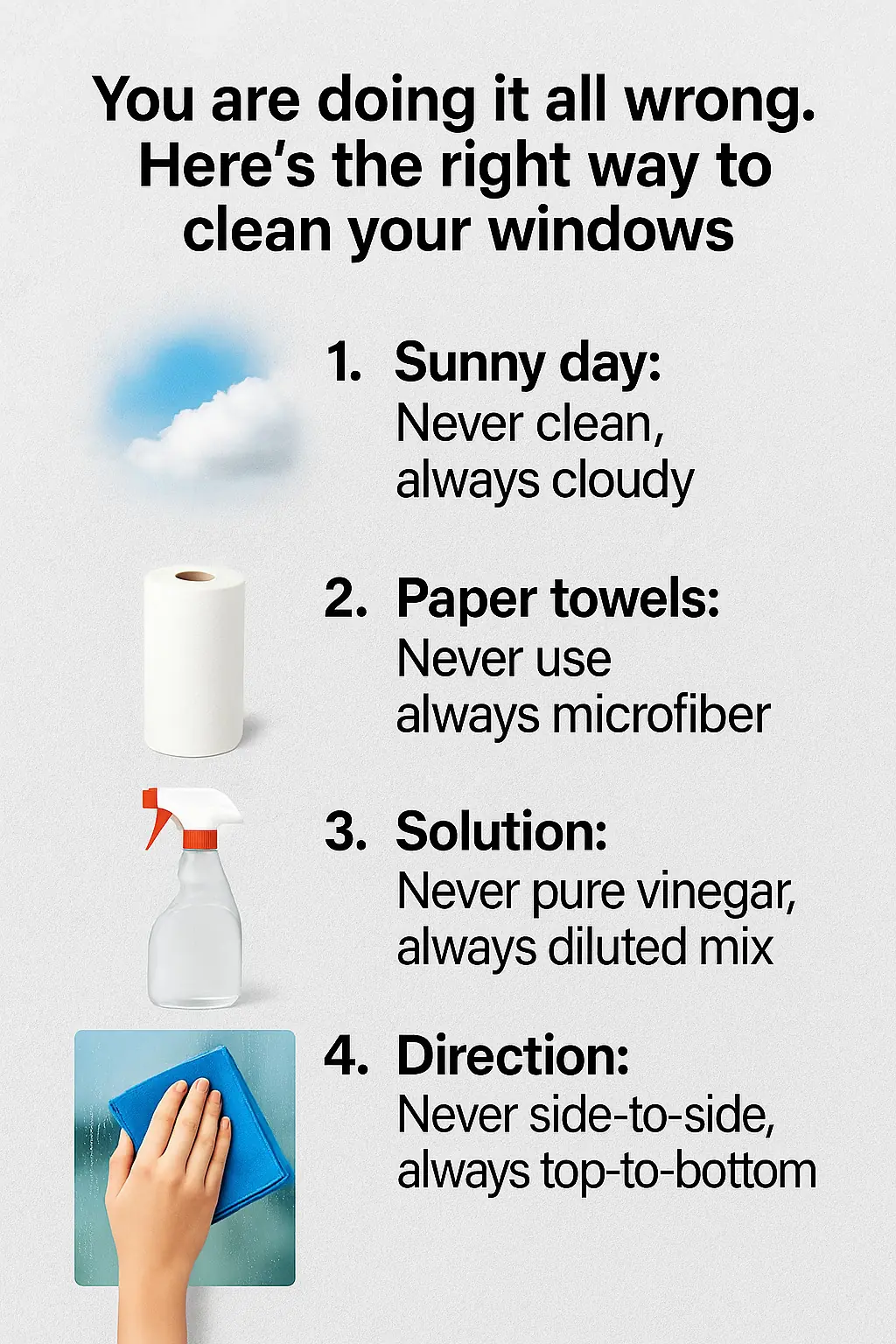

You are doing it all wrong. Here's the right way to clean your windows

My nana taught me this hack to whiten dingy grout in 4 mins with 0 work. Here’s how it works

You’re doing it all wrong. Here’s the right way to dust your home

News Post

5 Amazing Benefits Of Aloe Vera Gel For Skin: Large Pores, Dark Spots, Wrinkles

Clove & Lemon Collagen Drink: Wrinkle Free, Glowing Skin

Unlock Your Body’s Hidden Power: Try Garlic and Honey on an Empty Stomach for 7 Days

Tragus Piercing What Does It Mean

9 Health Benefits of Pine Needles

Unlock The Incredible Health Benefits of Garlic, Ginger and Lemon for Men

A special method to grow garlic in plastic bottles

7 Benefits of the Miracle Leaf of Life

7 Amazing Health Benefits of Banana Blossoms

Boiling Sweet Potatoes: Don’t Just Add Plain Water—Add This Spoonful for Perfectly Fluffy, Sweet Results

The Science Behind Putting a Cotton Swab in a Menthol Oil Bottle

More People Are Struggling with Visceral Fat — Doctors Reveal 9 Foods That Help Burn It Naturally

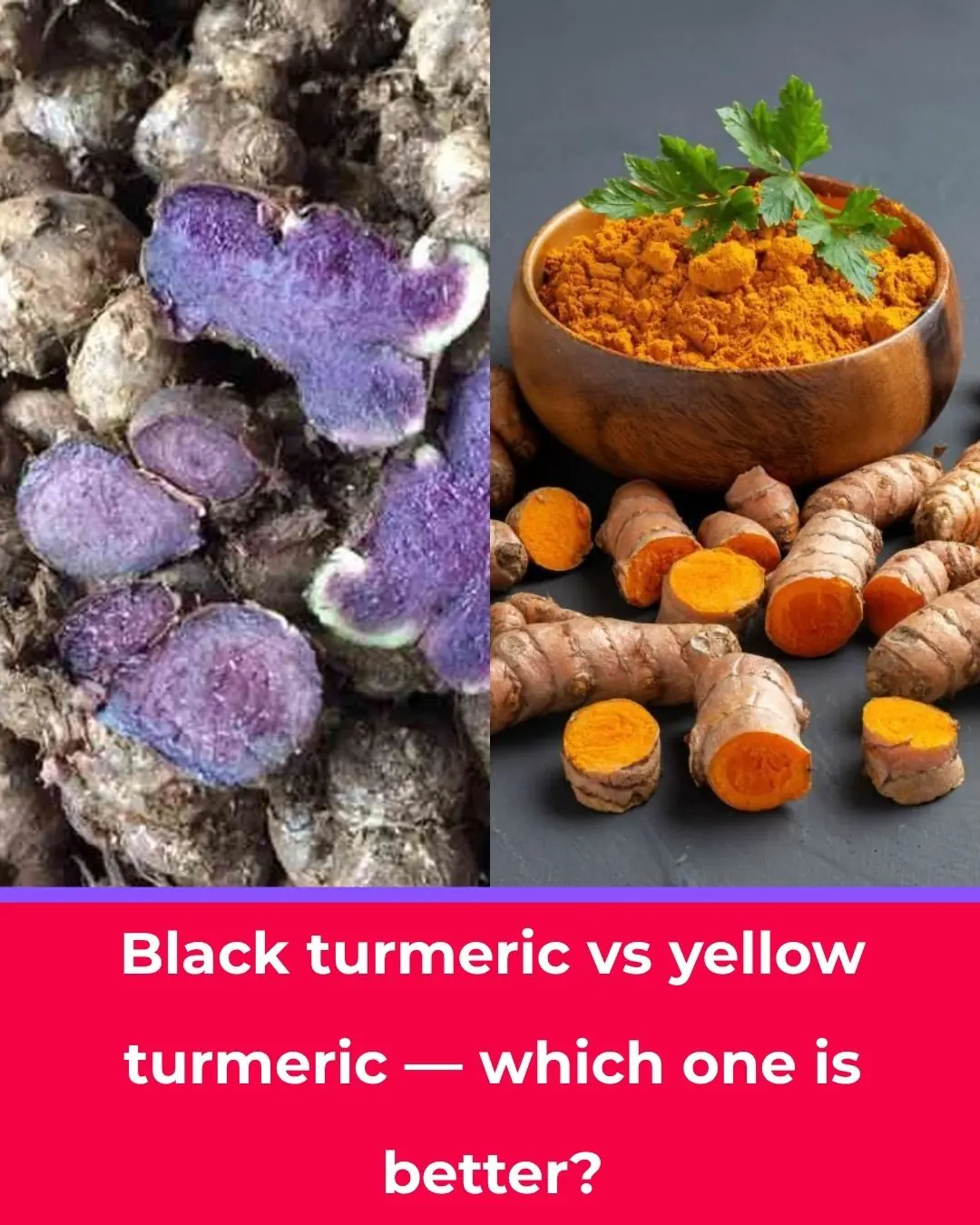

Black Turmeric vs. Yellow Turmeric: Which One Is Better?

Starve cancer: the diet rotation strategy you need to know

Like to see more from Tips for the Home

💪 Sarcopenia: Why Muscle Loss Happens & How to Fight It (After 50)

I Had No Idea About This!

These Ideas Are Amazing: 10 Clever Ways to Use Dryer Sheets Beyond the Laundry Room

Most Don’t Know: 13 Brilliant Ways to Use WD-40 Around the House