A Company in Kenya Builds Houses From Recycled Shipping Containers – Solar-Powered and Ready in Days

From Cargo Box to Family Home: The Rise of Container Housing in Kenya

On a Monday morning, a weathered shipping container sits in a Nairobi yard. By Thursday evening, it has transformed into a livable home, complete with solar power, running water, and painted walls. What once carried cargo across oceans now shelters a Kenyan family. Across the country, these steel boxes are being repurposed not only as houses, but also as offices, shops, and even classrooms.

Container conversion is emerging as a creative response to Kenya’s mounting housing challenges. With urban populations rising quickly and conventional construction often slow and costly, the appeal of a system that delivers a move-in-ready home within four days is obvious. Compared to the six to twelve months typically required for brick-and-mortar houses, container living represents a radical shift. Integrated solar panels add another layer of practicality, offering energy independence in regions where power blackouts remain common.

But with speed comes questions. How well do these structures hold up against Kenya’s varied climates, from humid coastlines to chilly highlands? What are the hidden costs of living in a container home? And, perhaps most importantly, who chooses this lifestyle—and why?

The Conversion Process: From Steel Box to Comfortable Shelter

Every transformation begins with a rigorous inspection. Teams assess rust levels, structural stability at the corner posts, and flooring integrity. Containers that pass the test move on to modification; those that fail are recycled as scrap metal.

The modification process is labor-intensive. Cutting openings for doors and windows requires careful reinforcement to maintain structural integrity. Welders add steel frames around each cut, while engineers calculate how weight and pressure will redistribute after the modifications.

Insulation follows, and it is perhaps the most critical step for ensuring comfort in Kenya’s diverse climates. Spray foam fills wall cavities, reflective barriers line the interiors, and vapor barriers prevent moisture build-up. Insulation needs differ by region: coastal areas require more humidity control, while highland regions need better thermal retention.

Next comes infrastructure. Electrical wiring snakes through conduits, plumbing connects to predetermined points, and solar panel mounts are secured to reinforced roof sections. Pre-planning dramatically reduces installation time, allowing specialist crews to work in parallel.

Once complete, every system faces inspection. Load testing checks the structural safety of modifications, wiring must meet certification standards, and plumbing undergoes pressure testing. Only when each stage passes inspection does the project move forward.

Harnessing the Sun: Solar Integration for Reliable Power

Container roofs, flat and sturdy, provide ideal platforms for solar panels. Standard systems involve 4–8 panels generating 1–2 kilowatts of electricity, enough for lighting, phone charging, laptops, and small appliances. For larger households, more extensive arrays are possible, though these require additional structural assessments.

Batteries, usually 2–4 lithium-ion units, store between 5–10 kilowatt-hours of energy. Smart inverters manage the balance between solar input, stored power, and grid connections where available. In Kenya’s coastal areas, households typically enjoy about five sun hours per day, while highland regions average slightly less. Rainy seasons reduce generation by up to 40%, making backup generators or grid connections essential.

Installation costs for solar systems typically range from 100,000 to 200,000 Kenyan shillings for a basic setup. While panels can last 20–25 years, batteries usually need replacement within a decade. For most families, the tradeoff is worthwhile, as solar often eliminates high electricity bills and shields households from blackouts.

Four Days to Move-In Ready

The speed of container construction is one of its biggest selling points.

-

Day 1: Crews prepare the site and position the container using cranes. Foundations—either concrete blocks or steel posts—are leveled for stability.

-

Days 2–3: Crews simultaneously handle wall framing, insulation, flooring, plumbing rough-ins, and electrical wiring. Pre-fabricated components allow multiple teams to work at once.

-

Day 4: Finishing touches include painting, fixture installation, and system testing. A final inspection clears the home for occupancy.

This rapid pace is possible because containers are already structurally sound, eliminating the need for curing concrete or waiting out weather delays. Still, more complex designs, additional containers, or remote delivery locations can extend timelines by weeks. Permit approvals also remain a potential bottleneck.

Cost Comparisons: Container Homes vs. Traditional Housing

Basic 20-foot container conversions cost between 600,000 and 1,000,000 Kenyan shillings, while 40-foot versions range from 1,000,000 to 1,500,000. By comparison, constructing a traditional house of similar size often costs between 1,500,000 and 3,000,000 shillings.

The shorter construction timeline also reduces indirect costs such as extended rental payments, loan interest, and exposure to fluctuating material prices. Solar integration further reduces monthly utility bills, although homeowners may face higher insurance premiums for unconventional structures.

Financing remains complicated. While some banks accept container homes as collateral, others do not, making loans harder to secure. Resale values are also uncertain since market data is limited, and public perception varies widely across Kenya.

Daily Life in a Container Home

A standard 20-foot container offers about 160 square feet of space—compact by most standards. A 40-foot version doubles that, while combining multiple containers allows for larger, modular homes. Still, ceiling heights average just 7.5 to 8 feet after insulation, leaving limited room for lofts or elevated storage.

Residents often report challenges with temperature regulation and noise. Well-insulated units stay comfortable, but poorly insulated ones become unbearably hot in coastal regions or too cold in highlands. Rainfall creates a drum-like sound on steel roofs, and additional soundproofing adds cost.

Families adapt with creative storage: built-in furniture, wall-mounted shelving, and external sheds. Maintenance includes monitoring for condensation, treating rust, and cleaning solar panels. Despite these efforts, some residents describe a sense of cramped living, particularly for larger families.

Kenya’s Climate Test

-

Coastal regions: Containers must resist high humidity and salt corrosion. Without protective coatings, deterioration begins within 5–7 years.

-

Highland regions: Wide temperature swings demand excellent insulation. Some households require extra heating during cold seasons.

-

Rainy seasons: Quality waterproofing determines durability. Poorly sealed modifications lead to leaks and interior damage.

-

Urban areas: Heat absorption in steel structures exacerbates the “urban heat island” effect, though reflective paint and tree shading can reduce heat by 20–30%.

Environmental Pros and Cons

Advocates highlight container conversion as large-scale recycling. Each unit saves nearly 3,500 kilograms of steel from waste. Rainwater harvesting systems integrate well, turning container roofs into collection points for storage tanks.

Yet the environmental record is mixed. Cutting, welding, and insulation all consume energy and produce waste. Paint and chemical residues also require careful disposal. While the carbon footprint is lower than building a new concrete house, it is not impact-free.

Challenges Few Acknowledge

-

Space constraints are particularly hard for families with teenagers or elderly members needing mobility support.

-

Social stigma lingers, with some neighbors perceiving container homes as temporary or substandard.

-

Technical expertise is scarce, especially in rural areas, leading to subpar conversions.

-

Regulation is inconsistent, with some counties supportive and others resistant.

-

Health concerns exist around insulation chemicals and poor ventilation. Long-term impacts remain under-studied.

Who Benefits—and Who Doesn’t

Container housing works best for single people, couples, or small families. It suits temporary land arrangements, rural plots without infrastructure, or anyone seeking a budget-conscious alternative. It is less suitable for households requiring multiple bedrooms, residents with health sensitivities, or communities with strict architectural rules.

Looking Ahead: The Future of Container Housing in Kenya

Today, container homes can be found from Mombasa to Nairobi, with construction companies reporting steady demand. Government agencies are testing container models for rapid housing deployment, while private developers see them as a possible solution for affordable housing.

Still, long-term durability data is scarce, as most container homes in Kenya are less than ten years old. Public acceptance is uneven, and industry quality varies widely. The future will depend on regulatory clarity, better technical training, and shifts in public perception.

Container homes are not a silver bullet for Kenya’s housing crisis, nor are they a passing fad. Instead, they represent one innovative option among many—blending speed, sustainability, and practicality, but also raising tough questions about comfort, financing, and long-term resilience.

News in the same category

What Terrible Things Happen When Women Lack Intimacy? A Painful Yet True Reality

Why You Should Never Place Your Bed Like This

Sink Trick You Should Always Do Before Vacation

Elon Musk Issues Serious Warning on Japan’s Population Decline

What it says about your relationship when your partner sleeps with their back to you

Orlando Bloom explains ‘horrible’ side effects his weight-loss transformation caused

A:dult star reveals the clause written into her contract that helps keep her safe

Bear Attack Survivor’s Haunting Farewell Note to Wife After Gathering Pieces of His Own Flesh

Ring Finger Longer Than An Index Finger

The Hidden Meaning Behind Thumb Rings for Women vs. Men

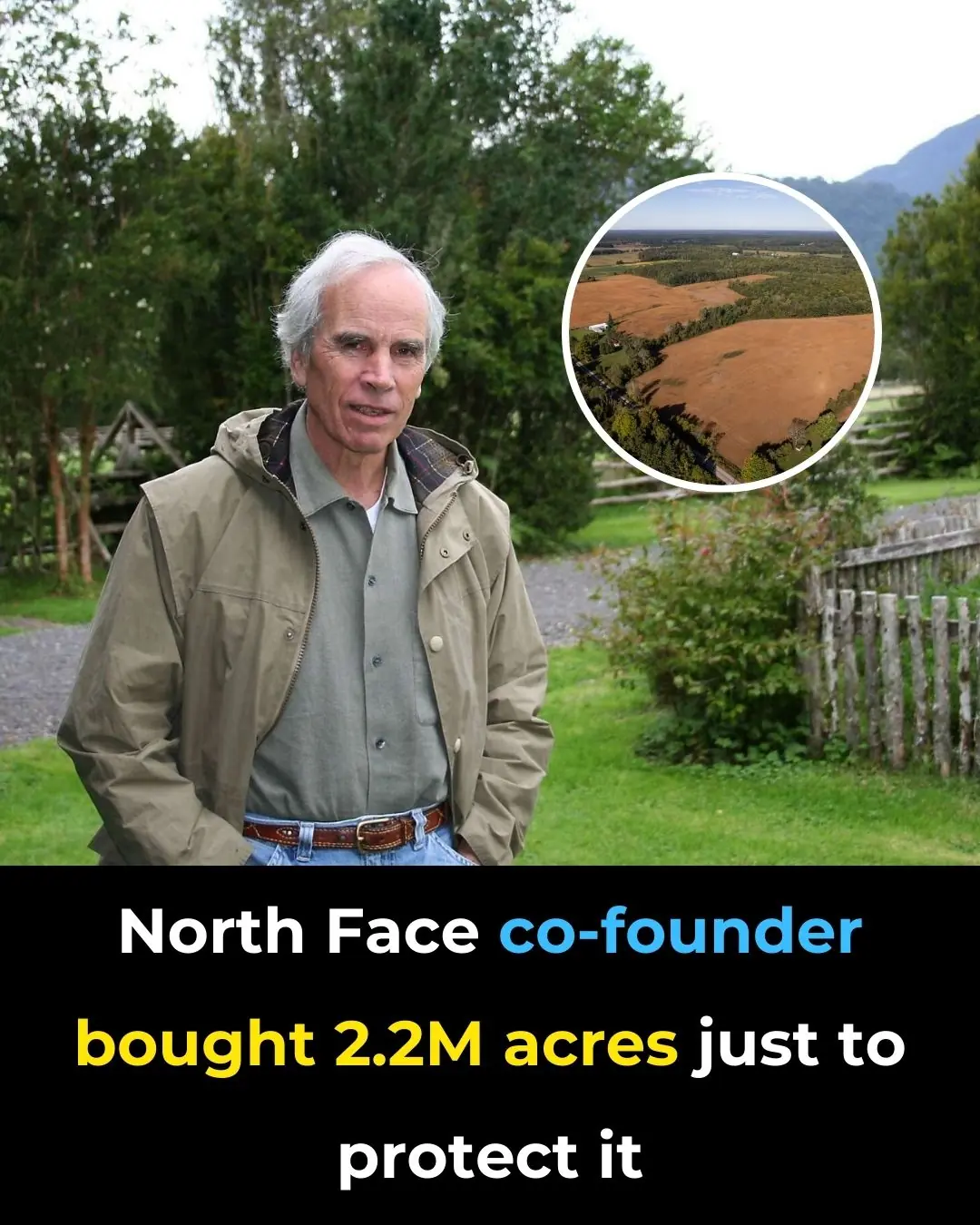

North Face Co-Founder Bought 2.2m Acres Just to Protect It

Family gives update on baby after brain dead woman was kept alive to give birth due to abortion law

The hidden meaning of thumb rings: what they represent for women vs. men

What it says about your relationship when your partner sleeps with their back to you

The World’s Strongest Animal Isn’t an Elephant or Bear

Gordon Ramsay issues health warning after undergoing cancer surgery

Delta Pilot Spends Year’s Salary to Fly 112 Friends to Hawaii for Epic Retirement Sendoff

Unbelievable footage shows moment Ukraine blows up two key Russian bridges using their own mines amid WW3 fears

News Post

🌿 Can Papaya Leaves Turn Gray Hair Black Naturally? Unlock Nature’s Secret to Vibrant Hair

Japanese airport has never lost luggage in over 30 years – This is why

The Ultimate DIY Clove Skincare Routine

5 Types of Drinks You Shouldn’t Store in a Thermos

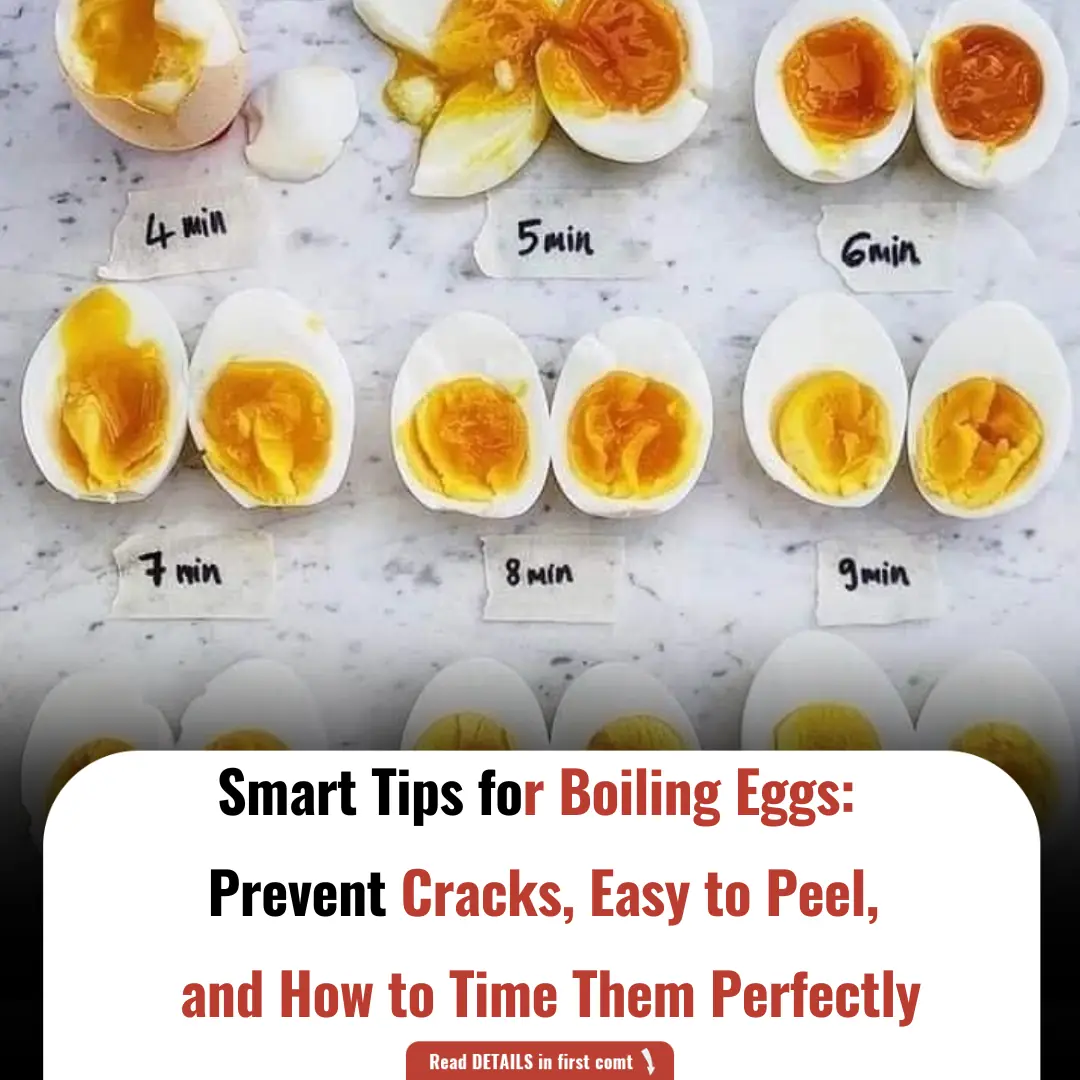

Smart Tips for Boiling Eggs: Prevent Cracks, Easy to Peel, and How to Time Them Perfectly

🥕 3-Day Carrot-Based Detox: Cleanse Your Liver and Intestines Naturally

Coconut Oil for Hair Growth – Add this in your Hair Oil

What Terrible Things Happen When Women Lack Intimacy? A Painful Yet True Reality

Why You Should Never Place Your Bed Like This

Sink Trick You Should Always Do Before Vacation

10+ Foods That Naturally Lower Blood Sugar Levels

Elon Musk Issues Serious Warning on Japan’s Population Decline

A Fruit Growing Abundantly in Gardens That Few People Eat Turns Out to Be an Autumn ‘Miracle’ Better Than Ginseng and Bird’s Nest

Why Should You Drop a Clove of Garlic into the Toilet Bowl at Night? Knowing Its Benefits, Every Household Wants to Try It

Revealed: How to Make Ceramic Tiles Sparkle at Home – Without Spending a Dime

If your private parts smell fishy, it’s something you should be aware of

Soak the vermicelli in a bowl of fish sauce, after 2 minutes you will know if the vermicelli is clean or contains borax.

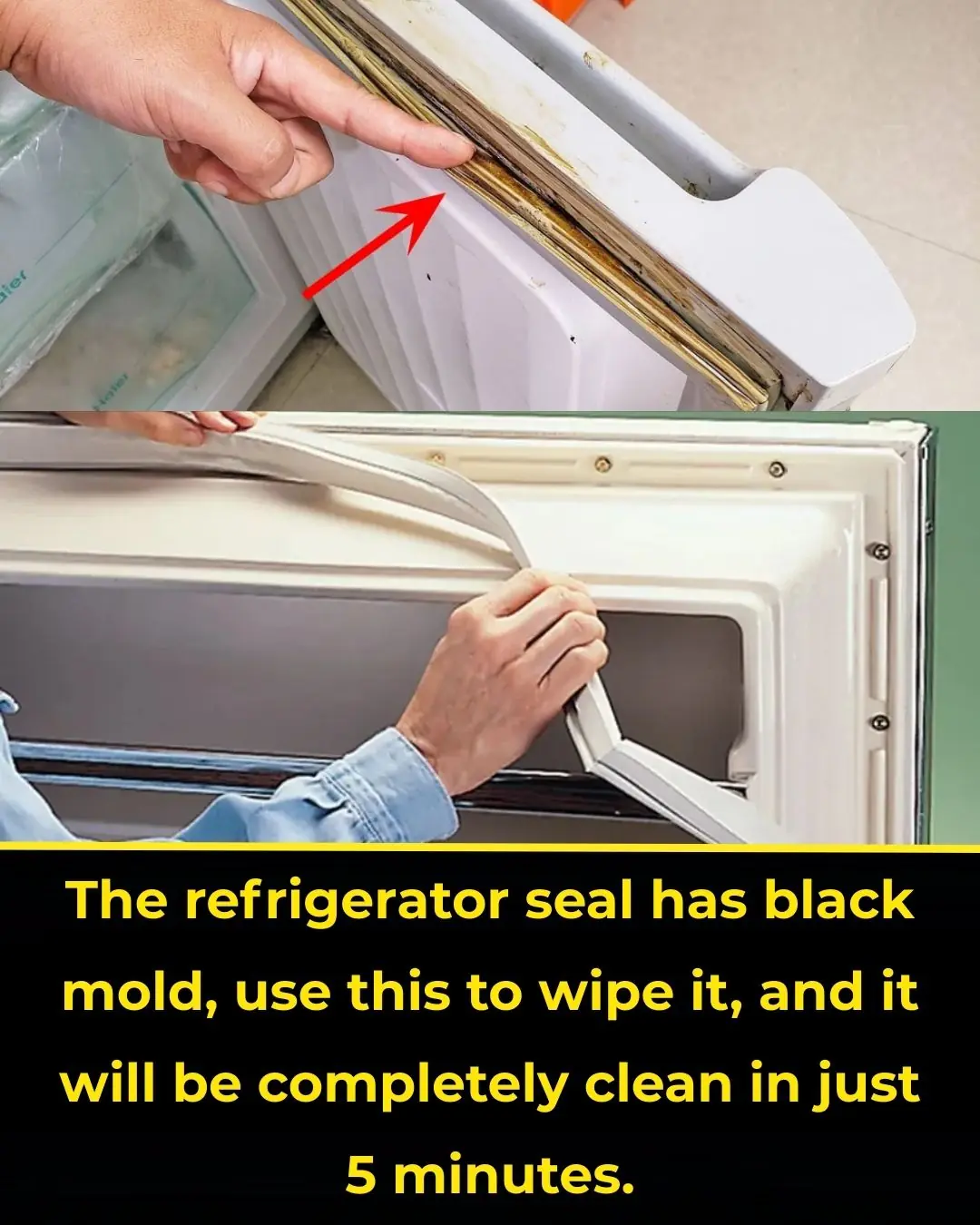

The refrigerator seal has black mold, use this to wipe it, and it will be completely clean in just 5 minutes.