Why are train wheels closer to a truncated cone than a perfect circle?

Have you ever watched a train roll by? If so, you may have wondered how the train stays on its tracks. The secret lies in the train’s wheels. While they appear cylindrical at first glance, upon closer inspection, you’ll notice that they have a slightly conical shape. (Of course, never get too close to a moving train!) This unique shape is what keeps the train on the tracks. In this article, we’ll explore why conical wheels are superior to other designs.

The wheels on each side of the train are connected to a metal bar called an axle. This axle keeps the two train wheels moving together, both rotating at the same speed as the train moves.

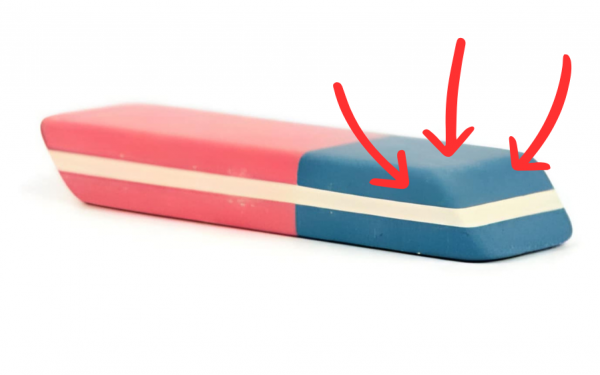

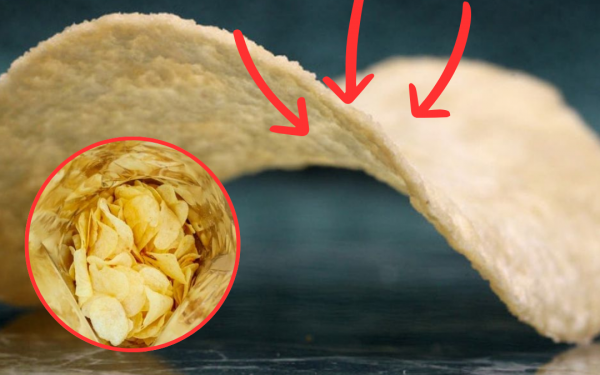

This configuration is great for straight tracks. But when the train needs to go around a curve, the fact that both wheels always rotate at the same speed can become a problem. The outside of the curve is slightly longer than the inside, so the wheels on the outside rail actually need to travel more distance than the wheels on the inside rail. Train wheels are not perfectly circular cylinders, but are designed to be almost conical (the larger diameter of the conical wheel points inward, the smaller diameter points outward) to ensure that the train does not derail and can easily go around the curve.

The slightly conical shape of the train wheel is an excellent engineering element that helps to adjust the train's path towards the center, while also helping the train achieve a differential effect, ensuring that the wheels do not derail.

The conical structure creates a self-centering force. When moving straight, the main forces act on the wheel. The passive forces are always perpendicular to the cone. The horizontal components of these forces cancel each other out so that the wheel self-centers.

The conical structure of the train wheel allows engineers to achieve a differential effect that helps the train run smoothly through curves.